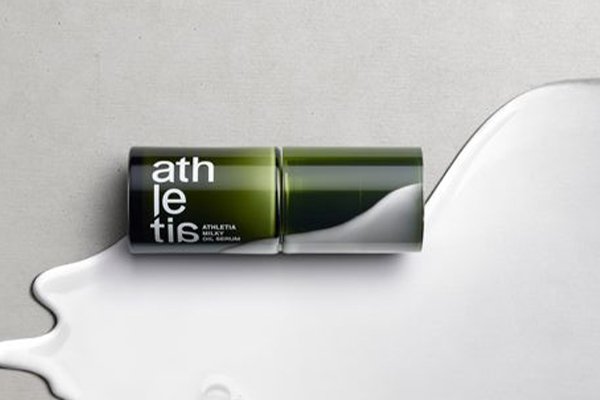

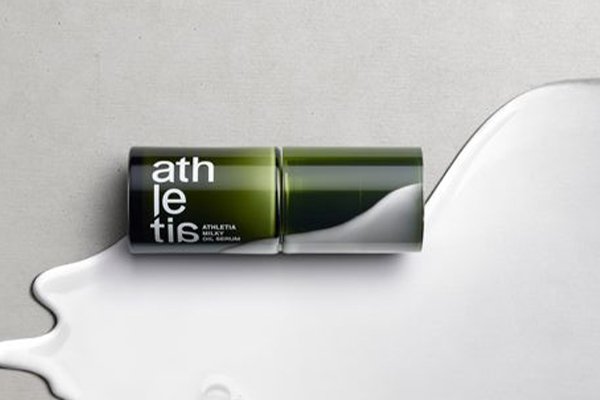

As consumers demand more eco-friendly products, PCR plastic is revolutionizing cosmetic packaging. But what makes it the future of the industry?

PCR plastic provides a sustainable alternative by utilizing recycled materials, helping brands reduce plastic waste, lower their environmental impact, and meet consumer demand for eco-friendly products, all while maintaining high-quality packaging standards.

Let’s explore the four key reasons why PCR plastic is transforming cosmetic packaging.

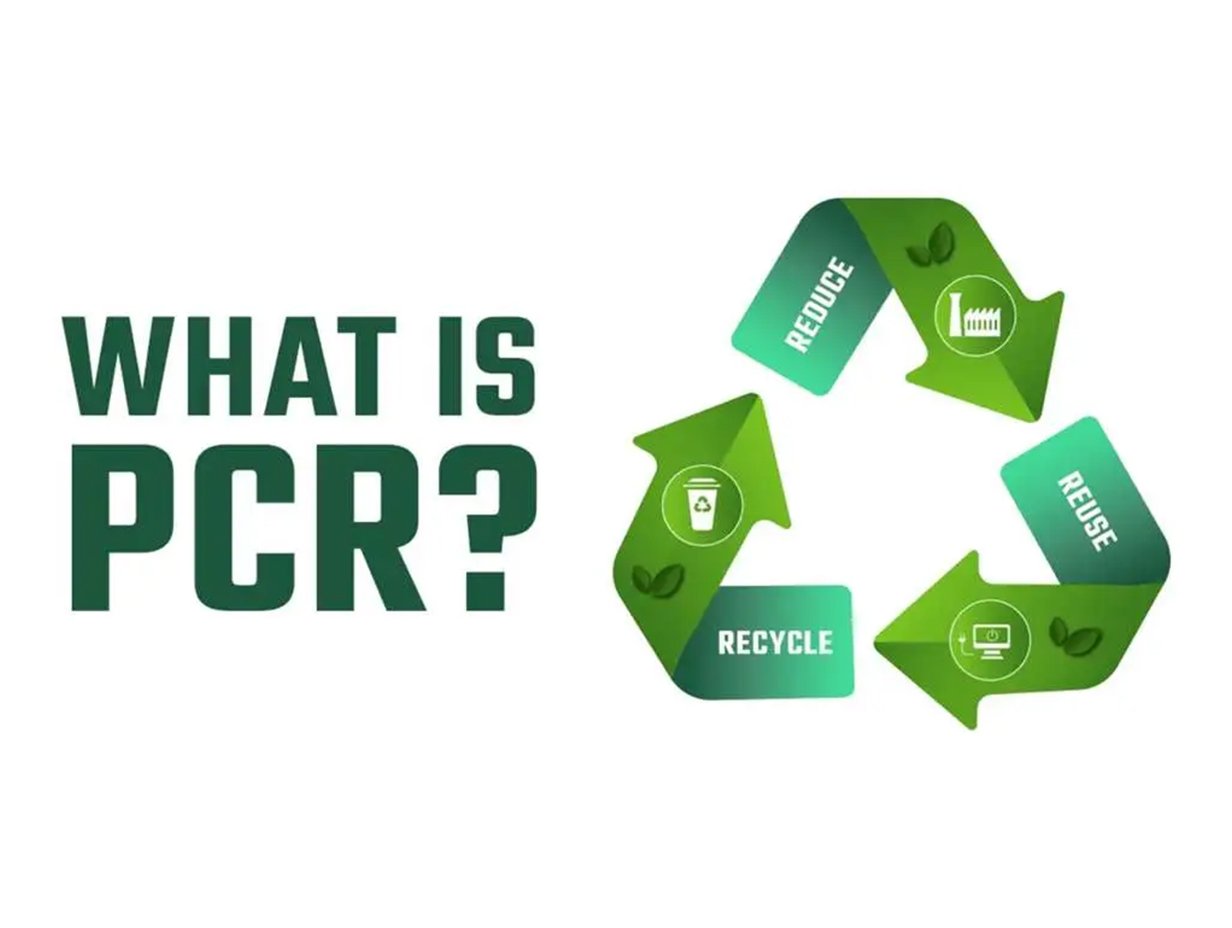

What is PCR (Post-Consumer Recycled) plastic?

Struggling with plastic waste1? PCR plastic2 offers a sustainable solution by recycling used materials into eco-friendly cosmetic packaging.

PCR (Post-Consumer Recycled) plastic2 is made from recycled used products, reducing virgin plastic demand and supporting sustainable cosmetic packaging.

PCR plastic helps reduce the demand for virgin plastic, supports recycling efforts, and is an eco-friendly choice for cosmetic packaging.

PCR plastic has become a cornerstone of sustainability3 in the cosmetic industry. By sourcing plastic from products already in circulation, PCR helps cut down on the need for new, virgin plastic. This process not only prevents additional plastic waste but also lowers the energy and resources used in production. As brands strive to meet eco-conscious demands4, adopting PCR plastic is a crucial step in aligning with sustainability goals3 and creating a circular economy3.

Benefits of Using PCR Plastic

| Benefit | Explanation |

|---|---|

| Sustainability | Reduces plastic waste by using recycled materials. |

| Lower Carbon Footprint | Manufacturing PCR plastic typically uses less energy than virgin plastic. |

| Cost Efficiency | Can sometimes be less expensive than virgin plastic, especially in large quantities. |

| Consumer Appeal | Eco-conscious consumers4 favor brands using sustainable materials. |

Benefits of Using PCR Plastic in Cosmetic Packaging1

Choosing PCR plastic significantly enhances the sustainability of cosmetic packaging. It minimizes waste and demonstrates a brand’s commitment to environmental responsibility.

By using PCR plastic, cosmetic brands can align with sustainability goals, reduce waste, and offer eco-friendly packaging1 to customers.

One of the main reasons PCR plastic is gaining popularity is its eco-friendly nature. With increasing consumer awareness4 of environmental issues, brands are under pressure to reduce their carbon footprint5. PCR plastic allows cosmetic companies to meet these demands without sacrificing product quality. Additionally, using recycled materials helps companies stand out in a crowded market where consumers increasingly prioritize sustainability3. Moreover, PCR plastic supports a closed-loop recycling system6, contributing to a circular economy3 that benefits both businesses and the environment.

How PCR Plastic Enhances Sustainability in Packaging

- Circular Economy: PCR plastic supports recycling and reuse, reducing overall plastic waste.

- Sustainable Sourcing: Brands can reduce their reliance on petroleum-based plastics by using recycled plastic7.

- Compliance with Regulations: PCR plastic helps brands meet stricter environmental regulations8 across many countries.

How to Integrate PCR Plastic into Your Cosmetic Packaging Line

Transitioning to PCR plastic can transform your packaging process sustainably. It requires careful planning and collaboration with the right partners.

Transitioning to PCR plastic involves sourcing the right suppliers, ensuring consistent quality, and adjusting production lines for recycled materials.

To incorporate PCR plastic into your cosmetic packaging line, the first step is sourcing reliable suppliers7 who provide high-quality recycled materials. Since PCR plastic can vary in quality, it’s important to partner with suppliers who can guarantee consistency in both material and performance. Next, you’ll need to modify your production processes to accommodate PCR plastic, which might involve adjusting your molding techniques. It’s also crucial to ensure that the end product meets the same high standards expected from traditional virgin plastic packaging, ensuring durability, appearance, and functionality.

Key Considerations for Integrating PCR Plastic

- Supplier Selection7: Work with suppliers who specialize in high-quality recycled materials.

- Production Adjustments9: Ensure your manufacturing process can handle the differences in PCR plastic.

- Quality Control10: Regular testing ensures that the end product meets quality standards and customer expectations.

The Challenges of Using PCR Plastic in Cosmetic Packaging

Adopting PCR plastic comes with hurdles that brands must navigate to ensure successful implementation and maintain quality standards.

Key challenges include inconsistent quality9, limited supply, and higher costs in some regions, but solutions exist for each.

The use of PCR plastic in cosmetic packaging is not without its challenges. One of the main concerns is the inconsistency in the quality9 of recycled plastic. Since PCR plastic is derived from post-consumer products, it can vary depending on the source. This can affect the appearance and durability of the packaging, leading to potential product complaints. Furthermore, while PCR plastic is gaining popularity, the supply chain can sometimes be unreliable, leading to delays or price fluctuations. Finally, in some regions, the cost of PCR plastic may still be higher than traditional materials, although this is expected to decrease as demand increases and production technologies improve.

Addressing the Challenges of PCR Plastic

- Quality Assurance10: Partner with trusted suppliers who provide consistent, high-quality PCR plastic.

- Supply Chain Management9: Build strong relationships with suppliers to ensure a steady, reliable supply.

- Cost Management9: Consider the long-term cost benefits of using PCR plastic, including potential cost reductions as production scales.

Conclusion

PCR plastic is an essential part of the future of cosmetic packaging, offering sustainability, cost efficiency, and a strong market appeal. Despite some challenges, the benefits far outweigh the limitations for forward-thinking brands.

-

Discover the advantages of PCR plastic for eco-friendly cosmetic packaging solutions. ↩ ↩ ↩

-

Learn more about PCR plastic and its role in sustainable packaging. ↩ ↩

-

Understand how PCR plastic contributes to a circular economy and reduces plastic waste. ↩ ↩ ↩ ↩ ↩

-

Explore how consumer preferences are shifting towards eco-friendly packaging solutions. ↩ ↩ ↩

-

Learn how using PCR plastic can help reduce the carbon footprint of cosmetic packaging. ↩

-

Discover the benefits of closed-loop recycling systems in maintaining sustainability. ↩

-

Explore methods and benefits of sustainable sourcing in plastic production. ↩ ↩ ↩

-

Find out how PCR plastic helps brands comply with environmental regulations globally. ↩

-

Learn about the common challenges faced when integrating PCR plastic into cosmetic packaging. ↩ ↩ ↩ ↩ ↩

-

Understand the importance of quality control when using recycled plastics in packaging. ↩ ↩