In a world where sustainability is becoming a priority, HDPE plastic has emerged as an ideal solution for cosmetic packaging. This material offers a perfect balance of durability, eco-friendliness, and customization options that appeal to both brands and consumers.

HDPE is a durable, recyclable plastic ideal for cosmetics packaging. Its strength, safety, and sustainability make it a top choice for the beauty industry.

Curious to learn why HDPE is a leading material in cosmetic packaging? Let’s explore its top benefits.

What is HDPE and Why is it Ideal for Cosmetic Packaging?

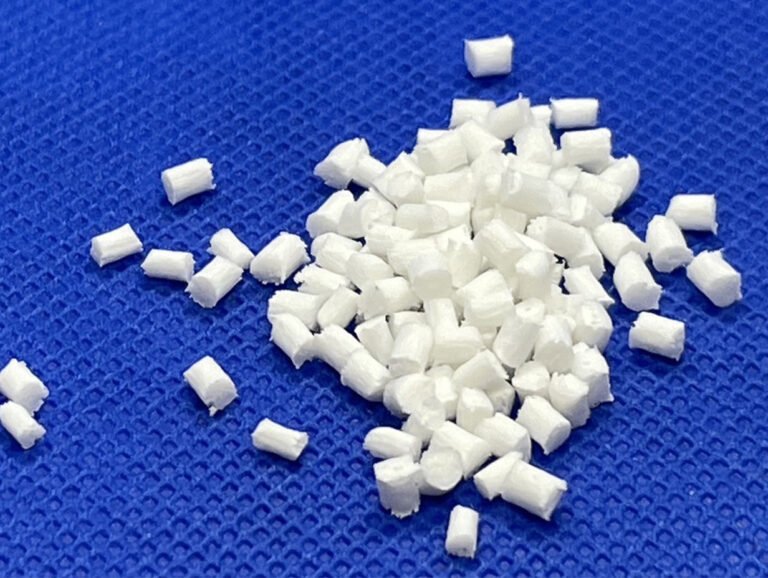

HDPE1, or High-Density Polyethylene2, is a thermoplastic polymer3 that has gained wide use across industries, especially in packaging4.

HDPE is a highly durable plastic commonly used in cosmetics packaging. It offers strength, chemical resistance5, and recyclability6, making it perfect for beauty products.

HDPE is a strong, lightweight thermoplastic3 material created by polymerizing ethylene7. It’s known for its high density, which makes it more durable than other plastic types like LDPE8. Its unique properties allow HDPE to resist stress, chemicals, and physical damage, which are essential qualities for packaging cosmetics that need protection during transport and handling.

Key Properties of HDPE:

- Durability: HDPE is highly resistant to cracks, dents, and impacts.

- Chemical Resistance: It doesn't react with oils, alcohols, or other ingredients commonly found in cosmetics.

- Moldability: HDPE can be molded into diverse shapes and sizes for customized packaging solutions.

| Property | HDPE Characteristics | Ideal for Cosmetic Packaging |

|---|---|---|

| Strength | Resistant to cracks, scratches, and physical impacts | Ideal for maintaining product integrity during shipping |

| Chemical Resistance | Does not interact with cosmetics' ingredients | Perfect for skincare products that contain oils or acids |

| Moldability | Easily molded into various shapes | Supports custom cosmetic packaging designs |

Why is HDPE Used in Cosmetic Packaging?

HDPE's superior qualities make it the perfect choice for cosmetic brands that value both product protection and sustainability9.

The high strength, chemical resistance, and customization options make HDPE a preferred material for cosmetics packaging, from skincare to makeup.

The cosmetic industry requires packaging that does more than just hold products. It needs to protect the contents, ensure safety, and provide branding opportunities. HDPE excels in all of these areas. The material's durability means it can withstand impact, reducing the risk of packaging damage during shipping. Its chemical resistance ensures that the packaging won’t react with the ingredients inside, which is crucial for preserving the quality of sensitive cosmetic formulations.

In addition, HDPE offers flexibility for customization. Brands can design unique packaging that suits their aesthetics and functional needs. Whether it's a sleek bottle, a convenient pump, or a stylish jar, HDPE provides endless design possibilities. Plus, its recyclability6 adds a sustainability factor that aligns with the growing demand for eco-friendly products.

Why Choose HDPE for Cosmetic Packaging:

- Durable and Safe: Protects cosmetic products from external elements and damage.

- Customizable: Offers design freedom, allowing for unique and branded packaging solutions.

- Eco-friendly: HDPE is fully recyclable, supporting sustainability efforts.

| Benefit | HDPE Characteristics | Why It Works for Cosmetic Brands |

|---|---|---|

| Durability | Resistant to physical damage | Ensures that cosmetic products remain intact during handling |

| Customizability | Can be easily molded and printed with logos | Provides opportunities for brand differentiation |

| Recyclability | 100% recyclable plastic | Reduces environmental impact, appealing to eco-conscious consumers |

Benefits of Using HDPE in Cosmetic Packaging

From cost-effectiveness to environmental impact, HDPE offers a range of benefits that make it a top choice for packaging cosmetics4.

HDPE offers numerous advantages, including durability, safety, and cost-effectiveness. Its recyclability also makes it a sustainable choice for cosmetic brands.

HDPE's benefits are numerous. First, its strength and impact resistance mean that packaging won’t break or crack easily, even during shipping or use. This is crucial for maintaining the integrity of the cosmetic products inside. Whether you're packaging face creams, lip glosses, or serums, HDPE ensures that your products arrive in perfect condition.

Furthermore, HDPE is lightweight, which reduces shipping costs, making it a cost-effective choice for brands. Despite its lightness, HDPE does not compromise on strength, ensuring your products are well-protected. It is also highly resistant to a range of chemicals, ensuring that it doesn’t react with the cosmetic products inside. This makes it an ideal option for both skincare and makeup products.

Another key advantage is its sustainability. HDPE is one of the most widely recycled plastics, making it an eco-friendly choice for brands looking to reduce their environmental impact. Many consumers are drawn to brands that prioritize sustainability, and using HDPE in your packaging can help appeal to this growing market.

Key Benefits of HDPE Packaging:

- Durable and Protective: HDPE provides excellent protection for delicate cosmetic products.

- Cost-Effective: Lightweight and durable, HDPE reduces shipping costs while maintaining product quality.

- Sustainable: HDPE is recyclable, making it an eco-friendly choice for brands aiming to reduce waste.

| Benefit | HDPE Characteristics | Benefit to Cosmetic Brands |

|---|---|---|

| Durability | Resistant to cracking and physical damage | Packaging stays intact during transport |

| Cost-Effectiveness | Lightweight, reducing shipping expenses | Lower shipping costs for bulk orders |

| Sustainability | Fully recyclable | Aligns with sustainability goals for eco-conscious consumers |

Common Uses of HDPE in Cosmetic Packaging

HDPE is used across various cosmetic packaging4 formats, providing flexibility and protection for a wide range of products.

From skincare bottles to makeup tubes, HDPE is used in a variety of cosmetic packaging formats, offering protection and flexibility.

HDPE's versatility makes it suitable for a wide range of cosmetic packaging applications. It’s frequently used for skincare bottles4, such as those for lotions, shampoos, and body creams. The material’s ability to withstand chemical interactions makes it perfect for these products, as it ensures that the packaging will not degrade or react with the contents inside. Similarly, makeup packaging such as foundation tubes, mascara containers, and lip gloss tubes often use HDPE because of its strength and resistance to external factors like moisture and dirt.

In addition, HDPE is commonly used for packaging items like sunscreen bottles, facial cleansers, and hair care products. Its lightweight nature ensures that products are easy to handle and transport, while its durability ensures they reach customers in excellent condition. Many high-end cosmetic brands also use HDPE for their luxury packaging because it can be customized into elegant, high-quality designs.

Common Applications for HDPE in Cosmetics:

- Skincare Packaging: HDPE is widely used for bottles and jars containing lotions, oils, and serums.

- Makeup Packaging: Ideal for lip gloss tubes, mascara containers, and foundation bottles.

- Hair Care Packaging: HDPE is used for shampoo bottles and conditioners due to its durability.

| Cosmetic Type | HDPE Packaging Use | Why HDPE Works |

|---|---|---|

| Skincare | Lotion bottles, body creams, face serums | Protects delicate formulas, lightweight |

| Makeup | Lip gloss tubes, mascara containers, foundation bottles | Offers durability and flexibility |

| Hair Care | Shampoo and conditioner bottles | Resists moisture and chemical exposure |

Conclusion

HDPE offers durability, customization, and sustainability, making it an ideal choice for cosmetics packaging. Its strength, cost-effectiveness, and eco-friendly benefits are unmatched, ensuring it meets the needs of modern beauty brands.

-

HDPE is defined as High-Density Polyethylene, a type of plastic known for its strength and durability. ↩

-

High-Density Polyethylene (HDPE) possesses properties such as high tensile strength and resistance to impact and chemicals. ↩

-

Thermoplastic polymers are materials that become pliable or moldable above a specific temperature and solidify upon cooling. ↩ ↩

-

LDPE, or Low-Density Polyethylene, differs from HDPE in density and flexibility, making HDPE more suitable for rigid packaging. ↩ ↩ ↩ ↩

-

HDPE is highly recyclable, supporting environmental sustainability by reducing plastic waste. ↩

-

Chemical resistance refers to HDPE's ability to withstand exposure to various chemicals without degrading. ↩ ↩

-

Sustainability in packaging involves using materials and processes that do not deplete resources or harm the environment. ↩

-

Cosmetic packaging refers to containers and packaging materials used to hold beauty and personal care products. ↩

-

Polymerizing ethylene is the chemical process used to produce HDPE, involving the linking of ethylene molecules into long chains. ↩