Pad printing offers unmatched precision and flexibility, making it the ideal choice for curved cosmetic packaging. But why is it superior to other methods?

Pad printing is a specialized method that effectively applies precise, durable, and vibrant designs onto curved surfaces. This makes it the preferred choice for cosmetic packaging, ensuring high-quality and visually appealing products that accommodate various shapes and contours.

Let’s explore how pad printing outperforms other techniques in cosmetic packaging.

What is Pad Printing?

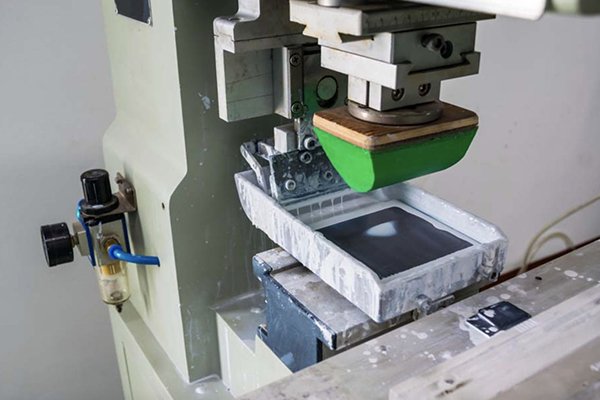

Pad printing is a versatile printing technique that transfers ink onto curved or irregular surfaces. It’s particularly suited for cosmetic packaging1.

Pad printing uses a silicone pad2 to transfer ink, making it perfect for printing on curved surfaces, like cosmetic packaging1.

Pad printing relies on a silicone pad2 to pick up ink from a printing plate3 and transfer it to a product surface. This method allows for printing on uneven or irregular surfaces like curved cosmetic containers. Unlike screen printing4, pad printing offers finer detail and higher precision5, making it ideal for printing logos, labels, or intricate designs on small packaging items such as lip gloss tubes, mascara bottles, and cosmetic jars.

Advantages of Pad Printing for Curved Surfaces

- Precision5: Pad printing’s silicone pad allows for fine lines and detailed prints.

- Versatility6: It can print on diverse materials and shapes, ideal for cosmetic packaging that comes in various forms and sizes.

- Cost-effective7: Compared to other methods, pad printing can be more economical for smaller print runs while maintaining high-quality results.

| Feature | Pad Printing | Screen Printing |

|---|---|---|

| Surface Compatibility | Curved/Irregular | Flat surfaces only |

| Print Detail | High precision | Lower precision |

| Setup Cost | Lower | Higher |

How to Print on a Curved Surface?

Printing on a curved surface can be tricky, but pad printing makes it simple. How does it work?

Pad printing’s silicone pad2 enables precise transfer of ink onto curved surfaces, ensuring high-quality prints on cosmetic packaging1.

The technique of printing on curved surfaces is made easy through pad printing's unique design. A silicone pad2 picks up ink from the etched plate, which can be shaped to fit the curvature of your packaging. This enables high-quality designs, logos, or text on surfaces that would be challenging for traditional screen printing4.

Why Pad Printing is Ideal for Curved Surfaces?

- Surface Conformity: The silicone pad2 conforms to the shape of the container, providing consistent and even prints.

- No Need for Perfect Alignment: Unlike screen printing4, there’s no need for perfect alignment with the printing surface. This flexibility makes it an ideal choice for cosmetic packaging, which often comes in unconventional shapes.

Considerations for Printing on Curved Surfaces

- Material: Some materials may require additional preparation to ensure the ink adheres properly.

- Size of the Design: Larger designs may require multiple passes to ensure full coverage.

| Material Type | Recommended for Pad Printing | Requires Special Handling |

|---|---|---|

| Glass | Yes | No |

| Plastic | Yes | Yes |

| Metal | Yes | No |

What Are the Capabilities of Pad Printing?

Pad printing offers a wide range of capabilities, but how far can it go when it comes to printing on cosmetic packaging?

Pad printing can produce fine, intricate designs on a variety of surfaces, perfect for customized cosmetic packaging1.

Pad printing’s capabilities go far beyond simple printing. With this method, you can achieve intricate, multicolored designs with sharp lines and fine details. It's perfect for printing on small cosmetic packaging like lip gloss tubes, eyeshadow cases, and foundation bottles, where high accuracy is required. Whether you want to create eye-catching designs or minimalist logos, pad printing offers unmatched precision5.

Customization for Cosmetic Packaging

Pad printing allows for easy customization of cosmetic packaging1. From brand logos to intricate designs, this method can bring any concept to life. Custom packaging options like these help businesses stand out in a competitive market.

Environmental Benefits

Pad printing is more environmentally friendly8 than some other printing methods. It uses less ink and generates less waste, making it a great option for brands looking for sustainable packaging solutions.

| Capability | Pad Printing | Other Methods |

|---|---|---|

| Design Precision | High | Medium |

| Customization | High | Low |

| Environmental Impact | Low | High |

What is the Difference Between Pad Printing and Screen Printing?

Is pad printing really better than screen printing for cosmetic packaging? Let’s compare the two.

While both techniques have their merits, pad printing outshines screen printing4 for curved cosmetic packaging due to its precision5 and flexibility6.

While both pad printing and screen printing4 are popular methods, they differ significantly in their application. Pad printing is ideal for printing on curved or irregular surfaces, making it perfect for cosmetic packaging1. On the other hand, screen printing is better suited for flat surfaces. Additionally, pad printing offers finer detail and more accurate color reproduction, which is crucial for cosmetic brands aiming for high-quality, detailed designs.

Advantages of Pad Printing Over Screen Printing

- Curved Surfaces: Only pad printing can handle printing on curved, cylindrical, or other irregular shapes.

- Fine Detail: Pad printing produces finer details and sharper lines compared to screen printing4, which may struggle with small fonts or intricate designs.

- Faster Setup: Pad printing requires less setup time than screen printing4, making it ideal for short production runs.

| Feature | Pad Printing | Screen Printing |

|---|---|---|

| Best for Curved Surfaces | Yes | No |

| Detail Level | High | Medium |

| Setup Time | Low | High |

Why Is Pad Printing the Preferred Choice for Cosmetic Packaging?

Struggling to find a printing method that handles curved surfaces with precision5? Traditional printing techniques often fail to deliver detailed, high-quality prints on irregularly shaped cosmetic containers. Pad printing offers the perfect solution, ensuring vibrant and precise designs on any curved surface.

Pad printing is a versatile technique ideal for cosmetic packaging1. It ensures high-quality, detailed prints on curved and irregular surfaces, making it perfect for products like lip gloss tubes and mascara bottles.

Dive Deeper into Pad Printing for Cosmetic Packaging

Pad printing is not just about transferring ink; it's about precision5, versatility6, and sustainability in cosmetic packaging. Let's explore the nuanced aspects that make pad printing a standout choice.

Environmental Impact of Pad Printing

Pad printing stands out for its eco-friendly approach compared to traditional methods. Here's how:

| Environmental Aspect | Pad Printing | Screen Printing |

|---|---|---|

| Ink Usage | Efficient, minimal waste | Higher consumption |

| Energy Consumption | Lower due to quicker setup | Higher due to extensive setups |

| Material Waste | Reduced through precise application | More waste from overspray |

Technological Advancements in Pad Printing

Advancements in pad printing technology have enhanced its capabilities, making it even more suitable for modern cosmetic packaging.

| Technology Feature | Description | Benefit |

|---|---|---|

| Automated Systems | Integration of robotics and AI | Increased precision and speed |

| Advanced Silicone Pads | Enhanced flexibility and durability | Better conformity to complex shapes |

| Digital Controls | Real-time monitoring and adjustments | Improved quality and consistency |

Cost-Benefit Analysis for Brands

Understanding the financial implications is crucial for brands considering pad printing.

| Cost Factor | Pad Printing | Alternatives (e.g., Screen Printing) |

|---|---|---|

| Initial Setup | Lower | Higher |

| Per Unit Cost | Economical for small runs | More cost-effective for large runs |

| Maintenance | Minimal | Potentially higher |

| Scalability | High flexibility for varying orders | Less flexible |

Case Studies: Successful Implementation

Examining real-world examples can provide insights into the effectiveness of pad printing in cosmetic packaging.

Case Study 1: Luxury Lipstick Brand

- Challenge: Required intricate designs on uniquely shaped lipstick tubes.

- Solution: Utilized pad printing for precise logo placement and detailed artwork.

- Outcome: Enhanced brand image and customer appeal.

Case Study 2: Organic Skincare Line

- Challenge: Sought sustainable packaging solutions without compromising on aesthetics.

- Solution: Adopted pad printing with eco-friendly inks.

- Outcome: Achieved eco-friendly packaging that resonated with the target audience.

Conclusion

Pad printing offers superior flexibility, precision, and eco-friendliness, making it the best choice for printing on curved cosmetic packaging.

-

Understand the various types and significance of cosmetic packaging in the beauty industry. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Discover the role and functionality of silicone pads in the pad printing process for better ink transfer. ↩ ↩ ↩ ↩ ↩

-

Learn more about the basics and processes involved in pad printing to gain a deeper understanding of how it works. ↩

-

Explore the differences between pad printing and screen printing to determine which method suits your needs. ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Find out why precision is crucial in pad printing for achieving high-quality and detailed prints. ↩ ↩ ↩ ↩ ↩ ↩

-

Learn about the versatility of pad printing and how it can adapt to different materials and shapes. ↩ ↩ ↩

-

Understand the cost benefits of pad printing, especially for smaller production runs. ↩

-

Discover the environmental advantages of pad printing and how it supports sustainable packaging efforts. ↩