LDPE plastic waste poses environmental challenges. Understanding its recycling can help mitigate these issues effectively.

LDPE plastic recycling involves specialized processes that convert waste into reusable materials, supporting sustainable skincare packaging and reducing environmental impact. These benefits include resource conservation, lower emissions, and promoting eco-friendly practices in the cosmetic industry.

Curious about how LDPE plastic recycling works and its environmental impact? Continue reading to uncover key facts and the benefits of this recycling process for both businesses and the planet.

What is LDPE Plastic?

Identifying LDPE plastic1 is the first step in effective recycling. But what exactly is Low-Density Polyethylene1?

LDPE, or Low-Density Polyethylene1, is a versatile plastic2 used in various packaging applications, including skincare packaging.

LDPE plastic, renowned for its exceptional flexibility and durability, is extensively utilized in a broad spectrum of packaging solutions. This includes skincare packaging, cosmetic skincare packaging, and eco-friendly packaging3 for skincare products. The inherent low density of LDPE makes it remarkably lightweight, which not only contributes to reducing transportation costs but also minimizes the overall environmental footprint associated with shipping and handling.

Furthermore, LDPE's excellent resistance to moisture, chemicals, and impact enhances its suitability for preserving the integrity and efficacy of skincare products. This resistance ensures that products remain uncontaminated and effective throughout their shelf life. However, despite these advantageous properties, the recyclability4 of LDPE is contingent upon meticulous sorting and processing. Unlike higher-density plastics such as HDPE or PET, LDPE poses more significant challenges in the recycling stream due to its lower melting point and greater flexibility, which can complicate the recycling machinery and processes.

Nonetheless, advances in recycling technology5 are continuously enhancing the efficiency and effectiveness of LDPE processing. These technological improvements are pivotal in enabling more sustainable practices6 within the skincare packaging industry. Innovations such as improved sorting mechanisms, better cleaning processes, and more efficient melting techniques are making it increasingly feasible to convert LDPE waste into high-quality recycled materials. This progress supports the transition towards a circular economy, where materials are reused and recycled continuously, thereby reducing the reliance on virgin plastics and mitigating environmental impact.

Types of LDPE Applications in Skincare Packaging

- Flexible Containers: Ideal for lotions and creams.

- Bags and Pouches: Used for sample sizes and single-use products.

- Film Packaging: Common for wrapping cosmetic products.

| Application Type | Description |

|---|---|

| Flexible Containers | Lightweight and durable for various skincare products, allowing for squeezable designs and easy dispensing. |

| Bags and Pouches | Convenient for samples and single-use packaging, enhancing user experience with resealable options. |

| Film Packaging | Versatile for wrapping and protecting products, offering clear visibility and tamper-evident features. |

Is LDPE Plastic Recyclable?

Many wonder about the recyclability4 of LDPE. Can LDPE plastic truly be recycled?

Yes, LDPE plastic is recyclable, though it requires specific processes to ensure effective recycling and reuse.

LDPE plastic is indeed recyclable, but the recycling process necessitates specialized facilities and meticulous handling to maintain the material's quality and integrity. The recycling journey for LDPE encompasses several critical stages: cleaning to eliminate any contaminants, melting the plastic to break it down, and reprocessing it into new, usable products. This transformation is essential for preserving the material's properties, ensuring that recycled LDPE can be effectively reused in various applications without significant degradation.

Recycling LDPE is particularly vital for sustainable skincare packaging6, where minimizing plastic waste aligns with environmental responsibility goals. However, the recyclability of LDPE is not universally supported across all recycling centers. Many facilities primarily focus on higher-density plastics like HDPE and PET, leaving LDPE underrepresented in the recycling stream. Therefore, it is imperative for consumers and businesses alike to consult local recycling guidelines to ensure that LDPE products are disposed of correctly and recycled efficiently.

Moreover, enhancing recycling infrastructure7 and increasing public awareness about the importance of LDPE recycling can significantly improve recycling rates. Educating consumers on proper disposal methods and encouraging the use of LDPE products with clear recycling symbols can facilitate better recycling outcomes. Additionally, investing in advanced recycling technologies and expanding the capabilities of recycling facilities to handle LDPE more effectively will support the adoption of more eco-friendly packaging3 solutions in the marketplace.

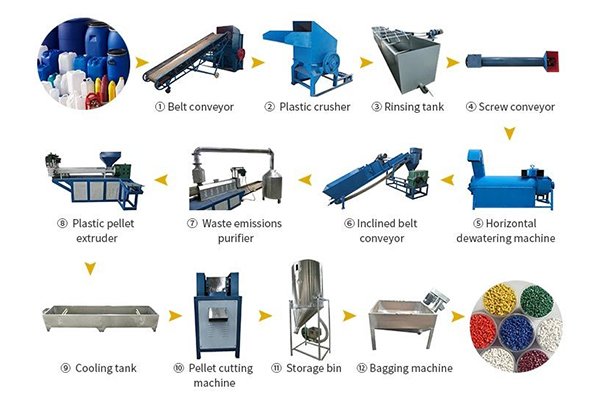

Recycling Process for LDPE Plastic

- Collection: Gathering LDPE waste.

- Sorting: Separating LDPE from other plastics.

- Cleaning: Removing contaminants.

- Reprocessing: Melting and forming into new products.

| Recycling Stage | Description |

|---|---|

| Collection | Gathering LDPE from various sources, including post-consumer waste and industrial scrap. |

| Sorting | Separating LDPE from other plastic types using mechanical or manual methods to ensure high-quality recycling. |

| Cleaning | Removing contaminants through washing and drying processes to prepare LDPE for melting. |

| Reprocessing | Melting and remolding LDPE into pellets or new products, ready for use in manufacturing. |

Challenges in Recycling LDPE Plastic

Despite its recyclability, LDPE faces several recycling challenges. What are they?

LDPE recycling is hindered by factors like contamination, limited facilities, and economic viability.

Recycling LDPE plastic presents significant challenges that impact its overall sustainability and efficiency. One of the primary issues is contamination8 of LDPE products, which can severely reduce the efficiency and quality of the recycling process. Contaminants such as food residues, adhesives, and mixed materials make it difficult to achieve a high-quality recycled product, as they can interfere with the melting and reprocessing stages, leading to material degradation and reduced usability in new applications.

Another major challenge is the limited availability of recycling facilities7 that specialize in processing LDPE. Many recycling centers prioritize higher-density plastics like HDPE and PET due to their widespread use and higher market demand for recycled materials. This scarcity of specialized facilities means that a substantial portion of LDPE waste is either landfilled or incinerated, contributing to environmental pollution and the loss of valuable recyclable material.

Economic factors also play a critical role in hindering LDPE recycling efforts. The costs associated with collecting, sorting, and processing LDPE can be prohibitively high, especially when the market value of recycled LDPE is low compared to the expenses involved. This economic imbalance discourages investment in LDPE recycling infrastructure and limits the scalability of recycling programs. Additionally, fluctuations in oil prices can affect the competitiveness of recycled LDPE versus virgin plastics, further complicating the economic viability of LDPE recycling initiatives.

Overcoming these challenges requires a multifaceted approach that includes improving waste management practices, advancing recycling technologies, and increasing consumer awareness about the importance of proper disposal and recycling of LDPE products. By addressing contamination issues through better sorting and cleaning processes, expanding the number of recycling facilities capable of handling LDPE, and creating economic incentives for recycling, the industry can move closer to achieving more sustainable and efficient LDPE recycling outcomes.

Major Barriers to LDPE Recycling

- Contamination: Residual materials like food, adhesives, and mixed plastics complicate the recycling process, reducing the quality of recycled LDPE.

- Facility Availability: Few recycling centers specialize in LDPE, limiting the overall recycling rates and availability of recycled LDPE products.

- Economic Factors: High processing costs and low market value for recycled LDPE deter investment and large-scale recycling initiatives.

| Challenge | Impact on Recycling |

|---|---|

| Contamination | Reduces quality and recyclability of LDPE, making it less desirable for reuse. |

| Limited Facilities | Decreases overall recycling rates, leading to more LDPE waste in landfills. |

| Economic Viability | Higher costs deter recycling initiatives, limiting the growth of LDPE recycling programs. |

How to Properly Recycle LDPE Plastic

Proper methods are key. How can LDPE plastic be recycled effectively?

Proper LDPE recycling involves sorting, cleaning, and processing to ensure reuse and sustainability.

Effective recycling of LDPE begins with meticulous sorting6 to separate LDPE from other types of plastics. This step is crucial to prevent contamination and ensure that the recycled material maintains its quality and suitability for reuse in various applications. Advanced sorting technologies, such as infrared spectroscopy and automated sorting systems, enhance the accuracy and efficiency of this process, enabling recyclers to distinguish LDPE from other plastic types more effectively.

Once sorted, the LDPE undergoes a thorough cleaning5 process to remove any residual contaminants. This typically involves washing the plastic with detergents and water to eliminate impurities like dirt, labels, adhesives, and other residues that could compromise the quality of the recycled material. Proper cleaning is essential to prevent degradation of the plastic during the subsequent melting and reprocessing stages, ensuring that the recycled LDPE retains its desirable properties.

After cleaning, the LDPE is processed7 by melting it down and reforming it into pellets or other reusable forms. These recycled pellets can then be used to manufacture new products, such as plastic lumber, automotive parts, or new packaging materials. This reprocessing step is fundamental to completing the recycling loop, transforming waste LDPE into valuable resources that support sustainable manufacturing practices.

Collaboration with reliable recycling facilities and responsible consumer disposal practices are fundamental to creating a sustainable LDPE recycling system. By ensuring that LDPE products are properly sorted, cleaned, and processed, the industry can significantly reduce the reliance on virgin plastics, lower environmental impact, and promote a circular economy where materials are continuously reused and recycled.

Steps to Recycle LDPE Effectively

- Sort: Separate LDPE from other plastics using mechanical or manual sorting methods to ensure purity.

- Clean: Remove residues, labels, and contaminants through washing and drying processes to prepare LDPE for recycling.

- Process: Melt and reform LDPE into reusable forms such as pellets or fibers, ready for manufacturing new products.

| Step | Action |

|---|---|

| Sorting | Separate LDPE from other plastics using advanced sorting technologies or manual methods to ensure high-quality recycling. |

| Cleaning | Ensure removal of all contaminants through thorough washing and drying, preventing impurities from affecting the recycled material. |

| Processing | Melt and convert LDPE into reusable forms like pellets or fibers, which can be used to create new products, thereby completing the recycling loop. |

What Happens to LDPE After Recycling?

Understanding the lifecycle matters. What becomes of LDPE post-recycling?

Recycled LDPE is transformed into new items, supporting a circular economy8.

After recycling, LDPE undergoes a transformation process that aligns with the principles of the circular economy**8, where materials are continuously repurposed to extend their lifecycle and reduce waste. This sustainable approach ensures that LDPE remains in use, minimizing the need for new plastic production and conserving natural resources.

Recycled LDPE can be converted into a variety of new products, each serving different industries and applications. One common end product is plastic lumber, which is utilized in outdoor furniture, decking, and other construction materials. Plastic lumber is highly valued for its durability, resistance to moisture, and low maintenance requirements, making it an excellent substitute for traditional wood products. Its weather-resistant properties ensure longevity, reducing the need for frequent replacements and lowering overall maintenance costs.

Another significant application of recycled LDPE is in new packaging, particularly for skincare and cosmetic products. Recycled LDPE can be molded into containers, bottles, and pouches, offering a sustainable alternative to virgin plastic packaging. This not only reduces the environmental impact but also meets the growing consumer demand for eco-friendly packaging solutions. Brands that adopt recycled LDPE packaging can enhance their sustainability credentials, appealing to environmentally conscious consumers and differentiating themselves in a competitive market.

Additionally, automotive parts represent another area where recycled LDPE finds its use. Components such as bumpers, interior trims, and fluid containers can be manufactured from recycled LDPE, contributing to the automotive industry's sustainability goals. Utilizing recycled materials in vehicle manufacturing helps reduce the overall carbon footprint of the automotive sector and promotes the use of sustainable materials in high-demand industries.

By transforming recycled LDPE into these valuable products, the material remains in circulation, minimizing waste and conserving resources. This practice not only benefits the environment by reducing plastic pollution but also supports businesses in achieving their sustainability targets and appealing to environmentally conscious consumers. As recycling technologies continue to advance and the infrastructure for LDPE recycling expands, the potential for LDPE to play a pivotal role in sustainable packaging solutions grows, ensuring that both businesses and the planet benefit from these efforts.

End Products from Recycled LDPE

- Plastic Lumber: Durable, weather-resistant material used for outdoor furniture, decking, and construction.

- New Packaging: Sustainable options for skincare and cosmetic products, reducing reliance on virgin plastics.

- Automotive Components: Reusable parts for manufacturing vehicles, enhancing sustainability in the automotive industry.

| Recycled Product | Description |

|---|---|

| Plastic Lumber | Durable, weather-resistant material suitable for outdoor furniture, decking, and other construction applications. |

| New Packaging | Sustainable packaging solutions for skincare and cosmetics, helping brands reduce their environmental footprint. |

| Automotive Components | Reusable parts such as bumpers, interior trims, and fluid containers that support the automotive industry's sustainability efforts. |

Conclusion

A deep understanding of LDPE recycling is essential for creating sustainable skincare packaging. By embracing this process, brands can reduce environmental impact, improve waste management, and contribute to a more eco-friendly future.

-

Learn more about LDPE to understand its properties and uses in various applications. ↩ ↩ ↩

-

Discover why LDPE is considered versatile and its advantages in different industries. ↩

-

Understand the advantages of using eco-friendly packaging solutions in the skincare industry. ↩ ↩

-

Understand the recyclability of LDPE and how it can be effectively reused. ↩ ↩

-

Explore the latest technologies improving the recycling process of LDPE. ↩ ↩

-

Find out how sustainable practices are implemented in skincare packaging using LDPE. ↩ ↩ ↩

-

Assess the existing recycling infrastructure and its capacity to handle LDPE waste. ↩ ↩ ↩

-

Learn about the circular economy and how recycled materials like LDPE contribute to it. ↩ ↩ ↩