PLA plastic is a popular sustainable option for cosmetics packaging, but is it safe and effective? Let’s explore the pros and cons in detail.

PLA plastic, made from plant-based materials, offers eco-friendly benefits, but its suitability and safety for cosmetics packaging require careful consideration.

Curious about how PLA stands up to cosmetics packaging needs? Let’s delve deeper into its key aspects.

What is PLA Plastic and How is It Made?

PLA plastic is a bioplastic1 derived from renewable resources like corn starch2 or sugarcane2. It is processed through fermentation3 and polymerization3 to create a versatile material used in various packaging solutions.

PLA plastic is derived from renewable plant materials like corn starch and sugarcane, offering a more sustainable option compared to petroleum-based plastics.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/What-is-PLA-Plastic-and-How-is-It-Made-1.jpg)

Production Process

| Step | Description |

|---|---|

| Raw Material Sourcing | Corn starch or sugarcane is harvested from sustainable farms. |

| Fermentation | Starch is converted into lactic acid through a controlled fermentation process. |

| Polymerization | Lactic acid molecules are linked to form polylactic acid (PLA)4. |

| Manufacturing | PLA is molded into packaging forms like bottles and jars using injection molding5. |

The production of PLA plastic begins with sourcing raw materials from renewable resources such as corn starch or sugarcane. These materials undergo fermentation, where microorganisms convert the starch into lactic acid. Through polymerization, lactic acid molecules are bonded to form polylactic acid, the primary component of PLA plastic3. Finally, the PLA is molded into various packaging forms, including bottles, jars, and tubes, which are commonly used in the cosmetics industry.

This sustainable production process not only reduces reliance on fossil fuels but also results in a lower carbon footprint compared to traditional petroleum-based plastics. By choosing PLA, cosmetic packaging manufacturers can align their products with eco-friendly practices, appealing to environmentally conscious consumers.

How Safe is PLA Plastic for Cosmetics Packaging?

PLA plastic is generally considered safe for cosmetics packaging. It is non-toxic and free from harmful chemicals like BPA6, which are often found in conventional plastics.

PLA plastic is generally safe for food contact, but its safety in cosmetics packaging depends on the specific product and packaging conditions.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/How-Safe-is-PLA-Plastic-for-Cosmetics-Packaging.jpg)

Safety Standards

| Safety Aspect | PLA Plastic |

|---|---|

| Non-Toxicity | Free from harmful chemicals like BPA and phthalates7. |

| Biodegradability | Breaks down naturally without releasing toxins. |

| Food Grade Compliance | Meets standards for safe contact with cosmetic products. |

Using PLA ensures that your cosmetic products remain safe for consumers, maintaining product integrity without compromising on health standards. Unlike traditional plastics that may leach harmful substances into products, PLA provides a safer alternative. This is particularly important for cosmetics, which are applied directly to the skin and sometimes ingested inadvertently.

In my experience working with various cosmetic packaging suppliers, I’ve found that PLA’s non-toxic nature reassures both manufacturers and consumers. It allows for the creation of packaging that not only protects the product but also aligns with the growing demand for safer, more sustainable packaging solutions.

Can PLA Plastic Maintain Cosmetic Product Quality?

Yes, PLA plastic can effectively maintain the quality of cosmetic products. It provides a reliable barrier against moisture and oxygen, preserving the product's efficacy.

While PLA provides a sustainable packaging option, its ability to protect and preserve cosmetics may not be on par with traditional plastics.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/Can-PLA-Plastic-Maintain-Cosmetic-Product-Quality.jpg)

Quality Preservation

| Factor | Impact of PLA Plastic |

|---|---|

| Moisture Barrier | Prevents water ingress, keeping products dry and stable. |

| Oxygen Barrier | Inhibits oxidation, extending product shelf life. |

| Structural Integrity | Durable enough to protect products during transit and handling. |

PLA's ability to maintain a stable environment for cosmetics ensures that the products remain effective and safe for use over time. Moisture and oxygen are two primary factors that can degrade cosmetic products, leading to reduced efficacy and shorter shelf lives. PLA provides an excellent barrier against these elements, ensuring that the contents remain fresh and effective.

In my work with JINLIN, we've observed that PLA packaging effectively preserves the quality of various cosmetic products, from lipsticks to lotions. The structural integrity4 of PLA also means that products are less likely to suffer damage during transportation, reducing waste and increasing customer satisfaction.

Enhanced Preservation Techniques

To further enhance the preservation capabilities of PLA, manufacturers can incorporate additional layers or coatings. For example, applying a thin barrier coating can improve PLA's resistance to oxygen, making it even more effective at maintaining product quality. Additionally, integrating antimicrobial agents8 into the PLA matrix can help prevent contamination, ensuring that cosmetic products remain safe for use over extended periods.

By prioritizing quality preservation, PLA plastic not only protects the cosmetic products but also builds trust with consumers who rely on the integrity and effectiveness of their beauty products.

What Are the Environmental Benefits of PLA in Cosmetics Packaging?

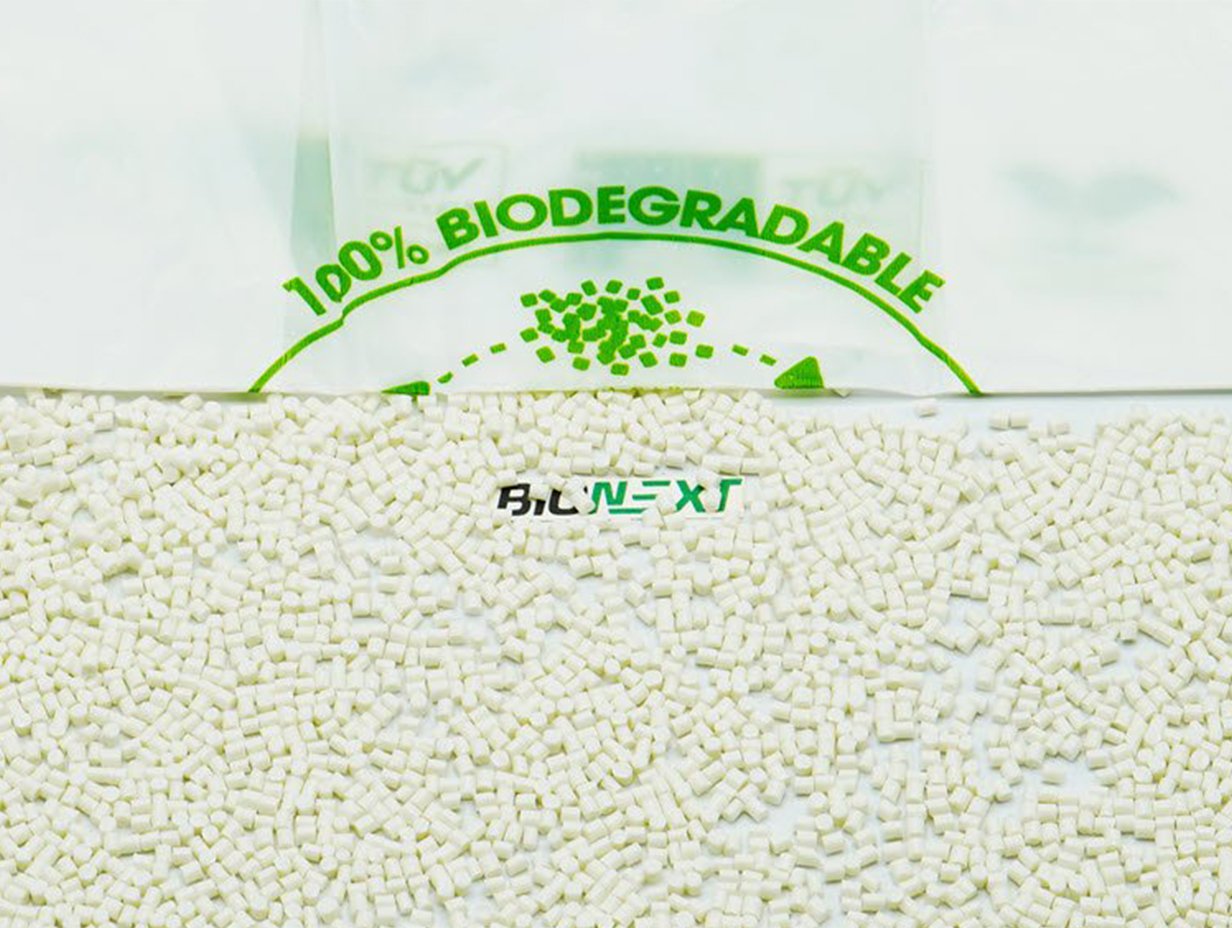

PLA plastic offers several environmental advantages over traditional petroleum-based plastics, making it a sustainable choice for cosmetics packaging.

PLA plastic’s renewable sources and potential for biodegradability make it an attractive option for eco-conscious brands looking to reduce their environmental footprint.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/What-Are-the-Environmental-Benefits-of-PLA-in-Cosmetics-Packaging.jpg)

Environmental Impact

| Benefit | Description |

|---|---|

| Renewable Resources | Made from plants, reducing dependence on fossil fuels. |

| Biodegradability | Decomposes naturally in industrial composting facilities[^8]. |

| Lower Carbon Footprint | Produces fewer greenhouse gases9 during production. |

Choosing PLA contributes to a greener planet by minimizing environmental harm and supporting sustainable practices in the cosmetics industry. Unlike conventional plastics that can take hundreds of years to decompose, PLA breaks down much more quickly under the right conditions, reducing long-term pollution and landfill waste.

In my journey with JINLIN, I’ve seen firsthand how adopting PLA packaging can significantly reduce a company’s environmental footprint. By switching to PLA, businesses not only comply with increasing environmental regulations but also cater to the growing consumer demand for eco-friendly products. This shift not only benefits the planet but also enhances the brand’s reputation as a responsible and sustainable entity.

Lifecycle Analysis

A comprehensive lifecycle analysis9 of PLA packaging reveals that its environmental benefits extend beyond biodegradability. The entire lifecycle—from raw material extraction to end-of-life disposal—demonstrates a lower environmental impact compared to traditional plastics. For instance, the cultivation of corn or sugarcane for PLA production absorbs carbon dioxide, helping to offset emissions. Additionally, the energy required for PLA production is generally lower than that for producing petroleum-based plastics, further reducing its overall carbon footprint.

By integrating PLA into your cosmetic packaging, you contribute to a sustainable lifecycle that benefits both the environment and your business.

What Are the Limitations of Using PLA for Cosmetics Packaging?

While PLA plastic has many benefits, it also has some limitations that businesses should consider before adopting it for cosmetics packaging.

PLA may not be the best option for every cosmetic product, as it faces limitations in terms of durability, protection, and recycling.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/What-Are-the-Limitations-of-Using-PLA-for-Cosmetics-Packaging.jpg)

Challenges and Considerations

| Limitation | Explanation |

|---|---|

| Thermal Sensitivity | PLA can deform at high temperatures, affecting packaging integrity. |

| Composting Requirements | Requires industrial composting facilities[^8], which may not be widely available. |

| Cost | Generally higher production costs compared to conventional plastics. |

Understanding these limitations helps in making informed decisions about integrating PLA into your cosmetic packaging strategy, ensuring that the benefits outweigh the drawbacks.

One of the main challenges with PLA is its thermal sensitivity. In environments with high temperatures, PLA can soften or deform, potentially compromising the integrity of the packaging and the safety of the cosmetic product inside. This is particularly relevant for products that may be exposed to heat during shipping or storage.

Additionally, while PLA is biodegradable, it requires specific conditions found in industrial composting facilities[^8] to break down efficiently. In regions where such facilities are not available, PLA may not degrade as intended, limiting its environmental benefits. This is an important consideration for businesses looking to market their products as fully sustainable.

Finally, the cost of PLA can be higher than that of traditional plastics. This can impact the overall pricing strategy for cosmetic products, especially for businesses operating on tight margins. However, as demand for sustainable packaging grows and production processes become more efficient, the cost gap between PLA and conventional plastics is expected to narrow.

Conclusion

PLA plastic offers a sustainable and safe option for cosmetic packaging, balancing environmental benefits with product quality.

-

Learn more about PLA plastic and its various applications. ↩

-

Understand what bioplastics are and their environmental advantages. ↩ ↩

-

Discover the fermentation process used to produce lactic acid. ↩ ↩ ↩

-

Gain insights into the injection molding process used for plastics. ↩

-

Learn about phthalates and their potential health risks. ↩

-

Understand the requirements for industrial composting of PLA. ↩

-

Compare the environmental impact of PLA and conventional plastics. ↩