Plastic injection molding is an essential process in cosmetic packaging, offering versatility and precision. Understanding how it works helps you make better decisions for your products.

Plastic injection molding is a widely used process for creating high-quality, customized cosmetic packaging. It involves injecting molten plastic into precisely designed molds to produce intricate, durable, and cost-effective packaging solutions for various cosmetic products.

Let's explore the core aspects of plastic injection molding and its role in cosmetic packaging.

What Is Plastic Injection Molding?

Plastic injection molding1 is the process of injecting molten plastic into a mold to create a wide variety of shapes. This process is essential for mass-producing2 products like cosmetic packaging.

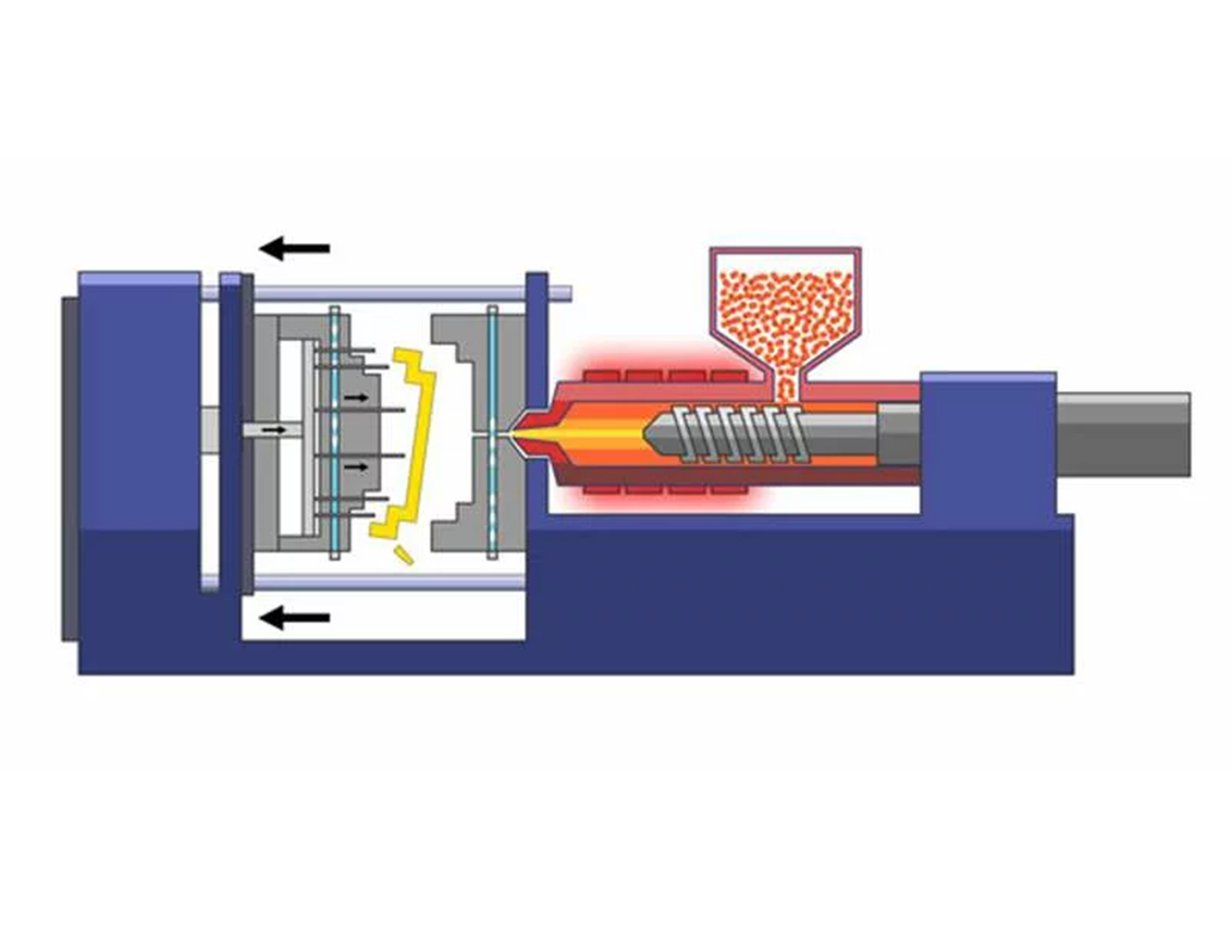

Plastic injection molding involves injecting molten plastic into molds under high pressure to form various shapes, widely used in cosmetic packaging for its efficiency.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/What-Is-Plastic-Injection-Molding.jpg)

Plastic injection molding has become a cornerstone of the cosmetic industry due to its ability to produce high volumes of consistent and precise packaging. The process begins with selecting the appropriate plastic material3, such as PET3, PP4, or ABS5, each offering unique properties suitable for different cosmetic products. The chosen plastic is melted and injected into a meticulously designed mold under high pressure. Once the plastic cools and solidifies, the mold opens, and the newly formed packaging is ejected. This method allows for the creation of intricate designs, including embossed logos, unique textures, and custom shapes, which are essential for luxury cosmetic packaging. Additionally, the automation6 inherent in injection molding ensures rapid production cycles, making it possible to meet the high demand of wholesale cosmetic packaging suppliers while maintaining superior quality standards.

Advantages of Injection Molding for Cosmetic Packaging

| Advantage | Benefit |

|---|---|

| High Precision1 | Ensures exact replication of designs |

| Cost-Effective for Mass Production2 | Reduces unit cost for large batches |

| Customizable Designs1 | Allows for unique and intricate packaging |

| Fast Production6 | Shortens time-to-market for new products |

This level of customization and speed makes plastic injection molding the go-to method for producing a wide range of cosmetic packaging solutions, from basic to luxurious.

What Are the Key Steps in the Injection Molding Process?

Understanding the steps involved in injection molding helps ensure better control over the production process. These steps are crucial for achieving high-quality cosmetic packaging.

The key steps in injection molding include material preparation3, mold setup, injection, cooling, and ejection. Each step ensures the production of high-quality cosmetic packaging.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/What-Are-the-Key-Steps-in-the-Injection-Molding-Process.jpg)

The injection molding process begins with material preparation, where the chosen plastic pellets are fed into a hopper and melted into a molten state. This molten plastic is then injected into a mold cavity at high pressure, ensuring that the material fills every detail of the mold. The design of the mold is critical, as it dictates the final shape and features of the cosmetic packaging, whether it's a sleek lipstick tube or an elegant eyeshadow case. After injection, the plastic is allowed to cool and solidify within the mold. Once cooled, the mold opens, and the finished product is ejected. The final step involves trimming any excess material and performing quality inspections to ensure each piece meets the required standards. This meticulous process allows cosmetic packaging manufacturers to produce large quantities of consistent, high-quality products efficiently.

Mold Design Considerations

- Detailing: Fine details, like embossed logos or intricate designs, are easily achieved through injection molding.

- Durability: Mold materials must be durable enough to withstand repeated use without degradation.

- Tolerances: Injection molds must be precisely engineered to ensure that the final product meets strict quality standards.

By carefully following these steps, manufacturers can produce high-quality cosmetic packaging that meets both aesthetic and functional requirements.

Why Is Injection Molding So Popular in Manufacturing?

Injection molding is widely popular in various industries, and cosmetic packaging is no exception. The process offers several benefits that make it the preferred method for producing packaging.

Injection molding is popular because it offers cost efficiency, speed, and high precision. It is especially beneficial for mass production of cosmetic packaging with consistent quality.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/Why-Is-Injection-Molding-So-Popular-in-Manufacturing.jpg)

One of the main reasons for the popularity of injection molding is its cost-effectiveness2. Once the mold is designed and built, it can be used to produce thousands or even millions of units. This mass production capability helps reduce the cost per unit, making it ideal for industries like cosmetics that require high-volume production at competitive prices. Another major benefit is the high precision of the process. Injection molding allows for the creation of complex and intricate designs with tight tolerances, which is essential for high-end cosmetic packaging. Whether you're looking for sleek lipstick tubes or unique, customizable packaging for luxury cosmetics, injection molding can deliver. Speed is another factor that drives its popularity. The process is highly automated, which speeds up production times and helps meet tight deadlines, crucial for cosmetic brands introducing new products to the market.

Why Injection Molding Works Well for Cosmetic Packaging

- Efficiency: Large quantities can be produced quickly and consistently.

- Customization: The process allows for unique designs and custom shapes.

- Quality Assurance: With automated systems, the quality of each piece is consistent.

Overall, injection molding’s ability to deliver high precision, speed, and low cost is why it remains a top choice in cosmetic packaging manufacturing.

What Materials Are Used in Injection Molding?

The material chosen for injection molding plays a crucial role in the final quality and functionality of cosmetic packaging. Let's explore the common materials used.

Common materials for injection molding in cosmetic packaging include PET, PP, and ABS, each offering specific advantages depending on the desired packaging qualities.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/What-Materials-Are-Used-in-Injection-Molding.jpg)

Cosmetic packaging manufacturers typically choose materials based on factors such as durability, clarity, and ease of molding. Common materials include:

- PET (Polyethylene Terephthalate)3: Often used for clear packaging like bottles and jars. It is strong, lightweight, and recyclable.

- PP (Polypropylene)4: A versatile plastic used for containers like cream jars and compact cases. It’s durable and resistant to chemicals.

- ABS (Acrylonitrile Butadiene Styrene)5: Known for its toughness and heat resistance, ABS is often used for more durable packaging solutions like lipstick tubes.

Each of these materials offers distinct benefits. For example, PET is ideal for creating clear cosmetic packaging, allowing consumers to see the product inside, while PP is commonly used for its flexibility and resistance to wear and tear. ABS provides the necessary durability for packaging that requires a sturdier structure. Selecting the right material depends on the type of cosmetic packaging you need and the properties required for durability, aesthetics, and functionality.

Material Comparison Table

| Material | Key Benefits | Common Applications |

|---|---|---|

| PET | Clear, lightweight, recyclable | Bottles, jars, and containers |

| PP | Durable, resistant to chemicals | Cream jars, compacts |

| ABS | Tough, heat-resistant | Lipstick tubes, applicators |

Choosing the appropriate material ensures that the cosmetic packaging not only looks appealing but also performs well in protecting and preserving the product inside.

What Are the Benefits of Plastic Injection Molding?

Plastic injection molding offers several advantages for cosmetic packaging, from cost savings to design flexibility.

The benefits of plastic injection molding include high precision1, customization options, speed, and cost-effectiveness, making it ideal for mass-producing cosmetic packaging.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/What-Are-the-Benefits-of-Plastic-Injection-Molding.jpg)

Injection molding offers several advantages for manufacturers looking to produce cosmetic packaging. Some key benefits include:

- High Precision: Injection molding is highly precise, ensuring exact replication of designs and features, which is crucial for maintaining brand consistency and quality in cosmetic packaging.

- Customization Options: The process allows for intricate and unique designs, enabling brands to create distinctive and attractive packaging that stands out in the market.

- Speed: Automated systems facilitate rapid production cycles, allowing brands to quickly bring new products to market and meet high demand efficiently.

- Cost-Effectiveness: Especially beneficial for large production runs, injection molding reduces the cost per unit, making it economically viable for mass production of cosmetic packaging.

These benefits make injection molding an ideal choice for companies producing cosmetic packaging in bulk. It enables them to keep costs low, speed up production, and maintain high-quality standards for their products. Additionally, the ability to customize designs helps brands differentiate themselves in a competitive market, offering unique and attractive packaging that appeals to consumers seeking both functionality and aesthetic appeal.

Advantages of Plastic Injection Molding

- High Precision: Ensures exact replication of complex designs and features.

- Customization: Facilitates the creation of unique and branded packaging solutions.

- Scalability: Easily scales production to meet high demand without compromising quality.

- Sustainability: Enables the use of recyclable and eco-friendly materials in packaging.

These advantages not only enhance the efficiency and effectiveness of production but also contribute to the overall success and sustainability of cosmetic brands in the market.

What Are the Challenges in Plastic Injection Molding?

While injection molding offers many benefits, it does come with certain challenges, especially in cosmetic packaging.

The challenges of injection molding include high initial setup costs2, mold maintenance, and limited material choices for certain designs.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/What-Are-the-Challenges-in-Plastic-Injection-Molding.jpg)

Despite its many advantages, there are challenges associated with plastic injection molding. One of the biggest hurdles is the high initial setup cost for creating the mold. Designing and producing molds can be expensive, especially for complex or custom shapes. However, this cost is offset by the reduced cost per unit for large production runs. Another challenge is mold maintenance. Since molds are used repeatedly, they can wear out over time, leading to the need for regular maintenance or replacement. This can lead to production delays and increased operational costs. Material limitations can also be a challenge. Certain designs may not be feasible with some materials due to their properties, such as rigidity or transparency. Manufacturers must carefully select materials to ensure they meet both the design and functionality requirements of the packaging. Additionally, achieving consistency in quality can be difficult when working with recycled materials7 like PCR plastic7, which may have varying properties. To overcome these challenges, companies invest in high-quality mold construction, regular maintenance schedules, and collaborate closely with material suppliers to ensure consistency and reliability in their production processes.

Addressing the Challenges of Injection Molding

- Quality Assurance: Partner with trusted suppliers who provide consistent, high-quality materials.

- Supply Chain Management: Build strong relationships with suppliers to ensure a steady, reliable supply.

- Cost Management: Consider the long-term cost benefits of using injection molding, including potential cost reductions as production scales.

By proactively addressing these challenges, cosmetic packaging manufacturers can leverage the benefits of plastic injection molding while minimizing potential drawbacks, ensuring efficient and sustainable production processes.

Conclusion

Plastic injection molding is vital for high-quality, sustainable cosmetic packaging solutions.

-

Provides a detailed definition and overview of plastic injection molding. ↩ ↩ ↩ ↩

-

Understanding the concept and benefits of mass production. ↩ ↩ ↩ ↩

-

Explains the properties and uses of PET in injection molding. ↩ ↩ ↩ ↩

-

Information on Acrylonitrile Butadiene Styrene (ABS) used in injection molding. ↩ ↩

-

Discusses the role of automation in the injection molding process. ↩ ↩

-

Explanation of Post-Consumer Recycled (PCR) plastic and its uses. ↩ ↩