Looking to innovate your cosmetic packaging? PLA plastic offers an eco-friendly alternative to traditional materials and aligns perfectly with sustainable cosmetic packaging trends.

PLA plastic is biodegradable, derived from renewable plant-based sources, and ideal for eco-conscious cosmetic brands. It reduces carbon footprints while providing versatile, safe packaging solutions for cosmetics.

Dive into the essential things you should know about PLA plastic and why it’s gaining popularity in the cosmetics packaging industry.

What Is PLA Plastic?

What exactly is PLA plastic (Polylactic Acid)1, and why is it considered an eco-friendly choice for cosmetic packaging? Let’s explore.

PLA plastic (Polylactic Acid) is a plant-based material made from renewable resources like corn or sugarcane2. It offers a sustainable alternative to traditional plastics3 for cosmetics packaging.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/What-Is-PLA-Plastic.jpg)

PLA plastic is a type of bioplastic4 derived from renewable plant starch2, particularly from crops such as corn, sugarcane, or cassava. Unlike conventional plastics3, which are petroleum-based and non-biodegradable5, PLA is derived from natural materials and can be fully composted6 under the right conditions.

The key benefit of PLA is its biodegradability5. When disposed of properly, PLA can break down into water and carbon dioxide in composting environments6, which helps reduce long-term plastic waste. It’s an excellent choice for companies looking to integrate more sustainable, eco-friendly practices in their cosmetic packaging lines, aligning with growing consumer demand for greener alternatives in packaging.

PLA’s versatility allows it to be used for a variety of cosmetic packaging formats, from jars and bottles to tubes and trays, making it an attractive option for beauty brands focused on eco-friendly packaging solutions.

Advantages of PLA Plastic

- Biodegradable: Breaks down naturally in composting environments.

- Renewable Resources2: Made from plant-based materials.

- Lower Carbon Footprint: Reduced emissions compared to traditional plastics.

- Versatile Design Options: Suitable for various packaging types.

Comparison of PLA vs Traditional Plastic

| Feature | PLA Plastic | Traditional Plastics |

|---|---|---|

| Source | Renewable (plant-based)2 | Petroleum-based |

| Biodegradability | Yes (Compostable) | No (Non-biodegradable) |

| Carbon Footprint | Lower | Higher |

| Production Efficiency | Lower energy usage | High energy consumption |

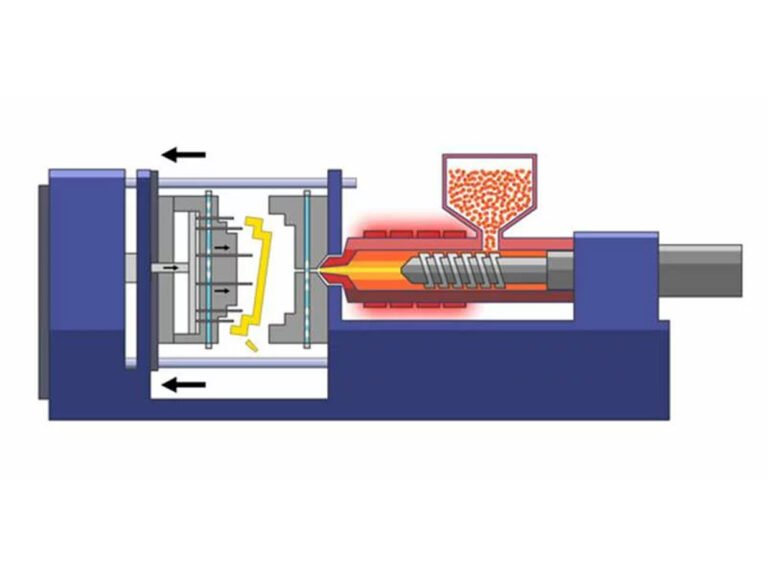

How Is PLA Plastic Made?

Wondering how PLA plastic is produced? Here’s a breakdown of the production process that makes it an eco-friendly choice for cosmetic packaging.

PLA plastic is created through a fermentation process7 of plant starch, which is then converted into lactic acid and polymerized to form plastic. This process is energy-efficient and supports sustainability.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/How-Is-PLA-Plastic-Made.jpg)

The production of PLA plastic begins with extracting starch from renewable plant sources, such as corn, sugarcane, or tapioca. This starch undergoes a fermentation process, during which it is converted into lactic acid. The lactic acid is then polymerized to form long chains, which are processed into plastic pellets. These pellets are subsequently used to create a wide range of packaging materials.

One of the major advantages of PLA’s production process is its energy efficiency7. Unlike traditional plastics, which require extensive oil extraction and refining, the creation of PLA is much less energy-intensive, significantly reducing the environmental impact. The use of plant-based materials also supports agricultural industries and promotes sustainability in the manufacturing sector.

Sustainable Production Practices

- Renewable Resources: Utilizes plant-based materials.

- Energy Efficiency: Lower energy consumption compared to petroleum-based plastics.

- Reduced Emissions: Lower greenhouse gas emissions during production.

Graph: Energy Consumption Comparison (PLA vs Traditional Plastics)

| Stage | PLA Plastic Production | Traditional Plastic Production |

|---|---|---|

| Raw Material Sourcing | Plant-based resources | Petroleum extraction |

| Energy Required for Production | Low | High |

| CO₂ Emissions | Minimal | High |

What Are the Benefits of PLA Plastic?

Let’s explore the key benefits of PLA plastic that make it a preferred choice for cosmetic packaging.

PLA plastic offers numerous benefits: it's biodegradable, compostable, made from renewable resources, and can help cosmetic brands reduce their environmental footprint.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/What-Are-the-Benefits-of-PLA-Plastic.jpg)

PLA plastic is not only eco-friendly but also offers various functional benefits for cosmetic packaging. Its primary advantages include:

- Biodegradability: PLA breaks down in industrial composting environments, reducing the risk of long-term plastic pollution.

- Renewable Resources: Made from plant-based materials, PLA reduces dependence on fossil fuels and supports sustainable agriculture.

- Versatility: PLA can be molded into a variety of packaging types, including bottles, jars, tubes, and more, which can be customized for cosmetic products.

- Carbon Footprint Reduction: PLA’s production emits fewer greenhouse gases compared to traditional plastics.

- Consumer Appeal: With increasing consumer demand for environmentally friendly products, using PLA plastic can enhance your brand’s image as an eco-conscious company.

Moreover, PLA’s transparency and glossy finish make it a popular choice for luxury cosmetic packaging, offering both sustainability and aesthetic appeal. This combination of environmental and aesthetic benefits makes PLA an ideal material for modern cosmetic brands looking to meet consumer demands for both functionality and sustainability.

Additional Benefits

- Lightweight: Reduces shipping costs and energy consumption during transportation.

- Durable: Offers protection for cosmetic products without adding unnecessary weight.

- Customizable: Can be easily colored and textured to match brand aesthetics.

List of Benefits:

- Eco-friendly and biodegradable

- Made from renewable resources

- Suitable for various cosmetic packaging formats

- Enhances brand sustainability image

- Attractive glossy finish

What Are the Applications of PLA Plastic?

Wondering where PLA plastic can be used in cosmetic packaging? The material’s versatility makes it ideal for multiple applications.

PLA plastic can be used for a variety of cosmetic packaging formats, including jars, bottles, tubes, and trays, offering both practicality and aesthetic appeal.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/What-Are-the-Applications-of-PLA-Plastic.jpg)

PLA plastic is used in a wide range of cosmetic packaging applications due to its versatility and aesthetic qualities. Some of the most common uses include:

- Cosmetic Jars: Ideal for creams, lotions, and other skincare products. PLA jars offer a sleek, modern look while being environmentally friendly.

- Bottles: Perfect for shampoos, body lotions, and serums, providing a smooth, glossy finish that enhances product presentation.

- Tubes: Often used for products like lip balms, foundations, and other beauty items, PLA tubes are lightweight and customizable.

- Trays & Inserts: Used to create custom inserts for packaging sets or as part of luxury cosmetic packaging, PLA trays can be designed to fit specific products perfectly.

These applications ensure that PLA plastic can serve as a sustainable alternative without sacrificing product integrity or aesthetic appeal. Whether you're looking for pretty cosmetic packaging or eco-friendly cosmetic packaging, PLA provides both.

Customization Options

- Colors: PLA can be easily colored to match brand themes.

- Textures: Offers various finishes, from matte to glossy.

- Shapes: Can be molded into unique shapes to differentiate products on the shelf.

Table: PLA Plastic Applications in Cosmetic Packaging

| Cosmetic Product | PLA Plastic Application |

|---|---|

| Lipstick Tubes | Customizable design and size |

| Lip Gloss Containers | Lightweight and durable |

| Skincare Jars | Eco-friendly, chic designs |

| Foundation Bottles | Sleek, transparent appearance |

| Makeup Brushes Holders | Stylish and sustainable |

Is PLA Plastic Safe for Food and Cosmetics Packaging?

Safety is a top concern when choosing packaging for cosmetics. So, is PLA plastic safe?

Yes, PLA plastic is FDA-approved7 for use in food packaging and is safe for cosmetics, as long as it meets the necessary standards.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/Is-PLA-Plastic-Safe-for-Food-and-Cosmetics-Packaging.jpg)

PLA plastic is safe for use in both food and cosmetic packaging as it is non-toxic8 and does not leach harmful chemicals. It has been approved by regulatory bodies such as the FDA7 for food contact applications, ensuring its suitability for cosmetics that may come into direct contact with skin.

It’s also important to note that PLA plastic, when used for cosmetic packaging, must meet strict production and testing guidelines to ensure it maintains the required level of safety and durability. Brands can offer their customers the reassurance that PLA packaging, when properly manufactured, is a safe and responsible choice.

Compliance and Certifications

- FDA Approval7: Ensures PLA is safe for food and cosmetic contact.

- ISO Standards7: Meets international quality and safety standards.

- Certifications: May include USDA BioPreferred or other eco-certifications.

Health and Environmental Safety

- Non-Toxic: Free from harmful chemicals like BPA.

- No Leaching: Maintains product integrity without contaminating cosmetics.

- Safe Disposal: Biodegradable nature reduces environmental hazards.

Regulatory Standards for PLA in Cosmetics

Ensuring PLA plastic meets all regulatory standards is crucial for safety and compliance. Cosmetic brands should verify that their PLA packaging suppliers adhere to necessary ISO standards and certifications to maintain product safety and consumer trust.

How Does PLA Plastic Compare to Traditional Plastics?

How does PLA plastic stack up against conventional plastic materials in the cosmetics industry?

PLA plastic is a more sustainable alternative to traditional plastics9, offering biodegradability and a smaller environmental footprint.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/How-Does-PLA-Plastic-Compare-to-Traditional-Plastics.jpg)

When compared to traditional plastics like PET or PVC, PLA plastic stands out for its environmentally friendly properties. Conventional plastics are made from petroleum, a non-renewable resource, and take hundreds of years to decompose. PLA, on the other hand, is made from renewable plant-based materials and is biodegradable, breaking down within months in the right composting conditions.

While PLA plastic can be more expensive to produce than traditional plastics, its sustainability advantages make it an attractive option for brands focusing on eco-conscious packaging. Switching to PLA can help brands meet sustainable cosmetic packaging goals while maintaining quality.

Comparative Analysis

- Environmental Impact: PLA has a lower carbon footprint and is biodegradable, unlike PET and PVC.

- Cost: Traditional plastics are generally cheaper, but PLA’s eco benefits can offset higher costs through brand value.

- Performance: PLA offers comparable durability and versatility but with added sustainability.

- Consumer Perception: PLA is favored by environmentally conscious consumers, enhancing brand reputation.

PLA vs Traditional Plastics in Cosmetic Packaging

| Aspect | PLA Plastic | Traditional Plastics |

|---|---|---|

| Environmental Impact10 | Biodegradable, renewable | Non-biodegradable, fossil-based |

| Cost | Higher production cost | Lower production cost |

| Durability | Comparable with proper handling | Highly durable |

| Versatility | High, customizable | High, but less eco-friendly |

| Consumer Appeal | Eco-conscious consumers | General consumer base |

Sustainability and Market Trends

The shift towards sustainability in the cosmetics industry is driving the adoption of PLA plastic. Consumers are increasingly prioritizing eco-friendly products, and brands are responding by choosing packaging materials that reflect their commitment to environmental responsibility. PLA plastic not only meets these demands but also offers a way to differentiate products in a competitive market.

Conclusion

PLA plastic is revolutionizing sustainable cosmetic packaging by offering biodegradable, renewable, and versatile solutions that meet both environmental and consumer demands.

-

Learn more about PLA plastic, its composition, and uses to understand why it is considered eco-friendly. ↩

-

Understand what bioplastics are and how they differ from conventional plastics. ↩ ↩ ↩ ↩

-

Discover the types of renewable resources used to produce PLA plastic and their benefits. ↩ ↩

-

Get a clear definition of biodegradability and its importance in reducing plastic waste. ↩

-

Learn about the composting process and how PLA plastic breaks down in such environments. ↩ ↩

-

Find out about FDA approval for PLA plastic and its safety in food and cosmetic packaging. ↩ ↩

-

Explore the ISO standards that ensure the quality and safety of PLA plastic used in packaging. ↩ ↩ ↩ ↩ ↩ ↩

-

Understand the USDA BioPreferred program and its significance for eco-friendly products like PLA plastic. ↩

-

Learn about PET and PVC plastics to compare them with PLA plastic in terms of environmental impact and usage. ↩

-

Discover the environmental consequences of using conventional plastics compared to PLA plastic. ↩