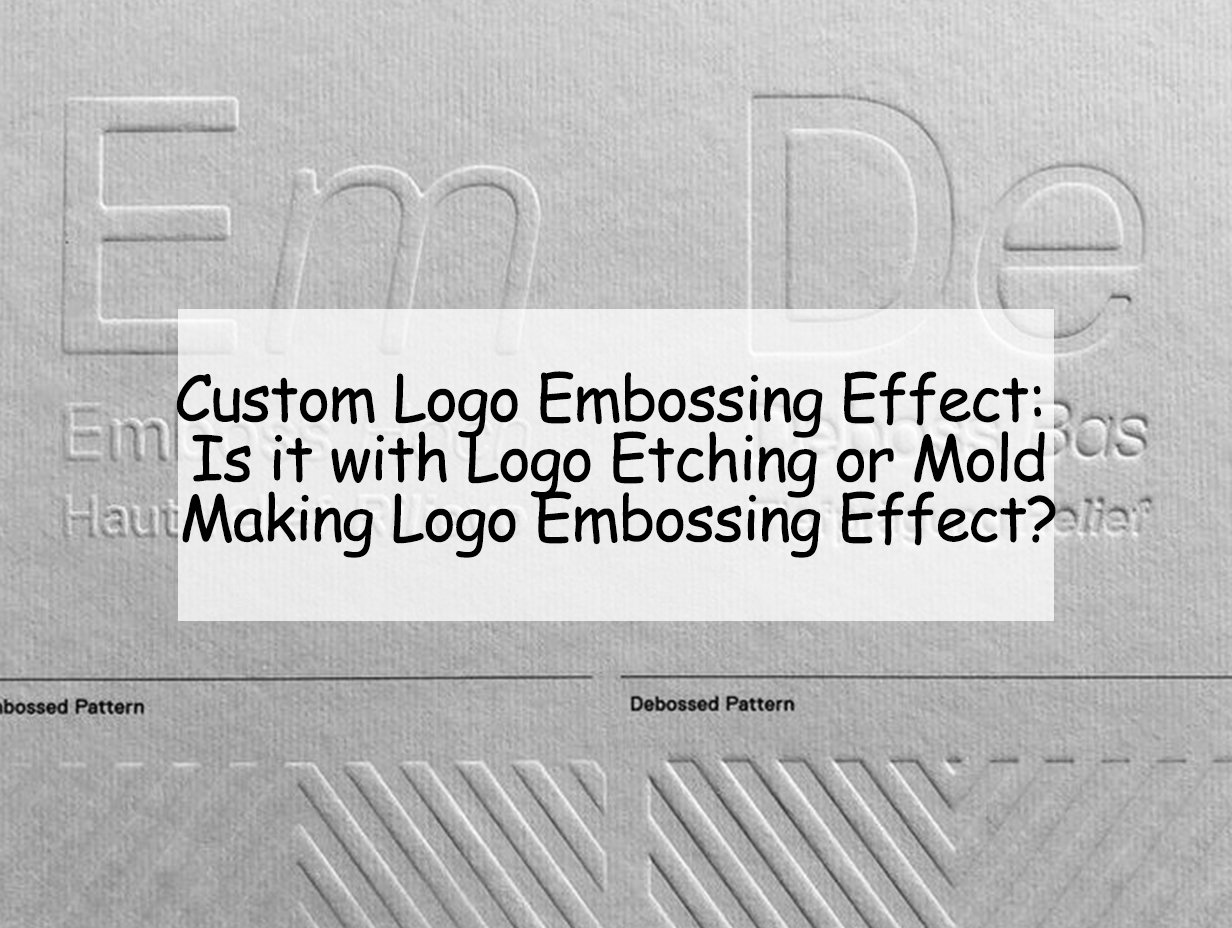

Are you unsure which embossing method to choose for your cosmetic packaging? Let's explore the key differences to make the best choice for your brand’s success.

Logo etching offers high precision, while mold making is ideal for larger production runs. Understanding both techniques will help you choose the right one for your packaging needs.

Understanding the differences between logo etching and mold making can significantly impact the quality and presentation of your cosmetic products. Let’s explore each method in detail.

What is Logo Etching and How Does it Differ from Mold Making in Cosmetic Packaging?

Confused about which embossing method suits your packaging needs? Let’s clarify the distinctions between logo etching1 and mold making2.

Logo etching involves engraving designs directly onto the packaging surface, offering high precision, while mold making uses specialized molds to create consistent embossing across large production runs.

Understanding the Techniques

Logo etching and mold making are two fundamental techniques used to create embossed effects on cosmetic packaging, each with its unique processes and benefits.

Logo Etching: This method uses lasers3 or mechanical tools to carve the logo directly onto the surface of the packaging material. The precision of etching allows for intricate and detailed designs, making it ideal for brands that prioritize unique and sophisticated aesthetics. Etching is particularly beneficial for smaller production runs where customization and detail are paramount. The process is relatively quick and flexible, allowing for easy adjustments to the design without significant additional costs.

Mold Making: In contrast, mold making involves creating a mold based on the logo or design, which is then used to emboss the packaging during the manufacturing process. This technique is highly efficient for large-scale production, ensuring that each piece of packaging has a consistent and uniform embossed logo. Mold making is cost-effective for bulk orders, as the initial investment in creating the mold is offset by the efficiency and speed of producing large quantities. However, it requires a longer setup time and less flexibility for design changes once the mold is created.

| Feature | Logo Etching | Mold Making |

|---|---|---|

| Precision | Extremely high for detailed designs | Consistent across all units |

| Cost | Higher per unit for small batches | Lower cost per unit for large orders |

| Setup Time | Shorter, suitable for quick changes | Longer due to mold creation |

| Flexibility | Easily adaptable to design changes | Requires new molds for different designs |

| Ideal For | Intricate, unique designs | Standardized, large-scale branding |

Choosing between these methods depends on your brand’s specific needs. If your focus is on detailed and unique designs with smaller production volumes, logo etching is the way to go. However, if you aim for consistency and efficiency in large-scale production, mold making is more suitable.

How Does Mold Making Work for Embossing Cosmetic Packaging?

Curious about how mold making can transform your packaging? Let’s break down the process and its advantages for your cosmetic products.

Mold making involves creating a master mold that consistently embosses your logo onto packaging, ensuring uniformity and high-quality finishes across all products.

The Mold Making Process

Mold making is a comprehensive process that ensures your cosmetic packaging stands out with a consistent and professional embossed logo.

Design Creation: The first step is to develop a precise design of your logo. This involves working closely with designers to ensure that the logo’s dimensions and details are accurately represented.

Master Model: Once the design is finalized, a master model4 is created. This can be a physical prototype or a digital model, serving as the blueprint for the mold.

Mold Fabrication: The master model is then used to fabricate the mold, typically made from durable materials like metal or silicone. The mold must be crafted with high precision to ensure that every embossed logo is identical and meets quality standards.

Integration into Manufacturing: The completed mold is integrated into the injection molding machine4. During production, the mold presses the logo onto the packaging material, creating a raised or recessed effect.

Quality Control: Each batch of packaging is inspected to ensure that the embossing is consistent and meets the desired quality. Any discrepancies are addressed to maintain brand integrity.

| Step | Description |

|---|---|

| Design Creation | Develop an accurate and detailed logo design |

| Master Model | Create a prototype or digital model of the logo |

| Mold Fabrication | Produce the mold based on the master model |

| Integration | Install the mold in the injection molding machine |

| Embossing | Consistently apply the embossed logo to packaging |

| Quality Control | Inspect and ensure uniformity and quality |

The mold making process is ideal for brands that require a high level of consistency across large production runs. It allows for efficient manufacturing, reducing the time and cost per unit when producing in bulk. Additionally, mold making supports various embossing depths and textures, providing versatility to match different branding needs and aesthetic preferences.

Is Etching a Better Option for Fine Details or Small Cosmetic Packaging Runs?

Wondering if etching is the right choice for your packaging? Let’s evaluate whether etching excels in creating fine details and supporting small production volumes.

Etching is ideal for achieving intricate details and is cost-effective for smaller cosmetic packaging runs, offering high-quality, detailed designs without extensive setup.

Benefits of Etching for Detailed Designs

Etching stands out when it comes to producing highly detailed and intricate designs on cosmetic packaging. This method employs precision tools like lasers or mechanical engravers to carve the logo directly onto the packaging surface. The result is a finely detailed embossing that captures every nuance of your design, making it perfect for brands that prioritize uniqueness and elegance.

For smaller production runs, etching is particularly advantageous. Since it doesn’t require the creation of a mold, the initial setup cost is significantly lower compared to mold making. This makes etching a more economical choice for limited batches, special editions, or niche product lines. The flexibility of etching allows for easy modifications to the design without incurring additional costs or delays, enabling brands to adapt quickly to market trends or seasonal changes.

Moreover, etching can enhance the tactile experience of your packaging. The precise engravings provide a subtle yet noticeable texture that customers can feel, adding a layer of sophistication and quality to the product. This sensory interaction can influence purchasing decisions, as consumers often associate textured packaging with higher value and better craftsmanship.

| Aspect | Etching | Mold Making |

|---|---|---|

| Detail Level | Extremely high for intricate designs | Consistent but less intricate |

| Production Size | Ideal for small to medium runs | Best for large-scale production |

| Setup Cost | Lower setup cost for small batches | Higher setup cost due to mold creation |

| Design Flexibility | Easily change designs | Requires new molds for design changes |

| Turnaround Time | Faster for smaller batches | Slower due to mold fabrication |

By choosing etching, you ensure that your cosmetic packaging not only looks exquisite but also stands out in a competitive market. The ability to create detailed and flexible designs without the constraints of mold making allows your brand to maintain a distinctive identity and cater to specific customer preferences.

Why Custom Logo Embossing Enhances Cosmetic Packaging Appeal?

Want to know how embossing5 can elevate your packaging? Let’s explore the ways custom embossing boosts the attractiveness and marketability of your cosmetic products.

Custom logo embossing adds both tactile and visual appeal to your packaging, making it more engaging and memorable for customers.

The Impact of Embossing on Brand Perception

Embossing your logo onto cosmetic packaging creates a unique sensory experience that can significantly influence how customers perceive your brand. The raised or recessed design not only catches the eye but also invites touch, enhancing the overall interaction with the product. This tactile element can make your packaging feel more luxurious and premium, elevating the perceived value of the cosmetic items inside.

Visual appeal is another critical factor. Embossed logos stand out on store shelves, attracting attention and differentiating your products from competitors. The intricate details of the embossing can highlight your brand’s commitment to quality and craftsmanship, reinforcing a sophisticated and professional image. Additionally, embossing can be combined with other design elements, such as foil stamping6 or spot UV6, to further enhance the visual impact and create a multi-dimensional effect.

Custom embossing also plays a vital role in brand recognition7. A well-designed embossed logo is more likely to be remembered by customers, fostering brand loyalty and repeat purchases. The consistent presence of your embossed logo across all packaging reinforces brand identity, making it easier for customers to recognize your products in various settings.

| Benefit | Description |

|---|---|

| Tactile Experience | Engages customers through touch |

| Visual Appeal | Enhances the aesthetic look of the packaging |

| Brand Recognition | Makes the logo more memorable and identifiable |

| Perceived Quality | Elevates the product’s luxury and premium feel |

| Differentiation | Sets your brand apart from competitors |

Incorporating custom embossing into your packaging strategy not only improves the physical appearance of your products but also strengthens your brand’s presence in the market. It communicates attention to detail and a dedication to quality, which are essential attributes for attracting discerning customers in the cosmetic industry.

Eco-Friendly and Sustainable Cosmetic Packaging with Embossed Logos

Interested in sustainable8 packaging solutions? Let’s discuss how embossed logos can contribute to eco-friendly cosmetic packaging without compromising on quality or aesthetics.

Embossed logos can be created using sustainable materials and processes, reducing environmental impact while maintaining high-quality packaging standards.

Sustainable Practices in Embossing

Sustainability8 is a growing concern in the cosmetic industry, and integrating eco-friendly practices into your packaging can enhance your brand’s reputation and appeal to environmentally conscious consumers. Embossing can be aligned with sustainable packaging efforts in several ways.

Material Selection: Choosing recyclable9 or biodegradable8 materials for your packaging is the first step towards sustainability. By using eco-friendly substrates, such as recycled paperboard9 or bioplastics8, you can minimize the environmental footprint of your products. Embossing these materials enhances their aesthetic appeal without adding harmful substances, ensuring that your packaging remains both beautiful and responsible.

Eco-Friendly Inks and Finishes: Opting for water-based inks10 or vegetable-based inks10 for any additional printing complements the sustainability of embossed packaging. These inks are less harmful to the environment and reduce the overall ecological impact of the packaging process. Additionally, avoiding toxic finishes and coatings ensures that the entire packaging solution remains green.

Energy-Efficient Processes: Implementing energy-efficient machinery4 and processes in the embossing operation can further reduce environmental impact. Modern injection molding machines4 and laser etching tools3 are designed to consume less energy while maintaining high precision and quality. Additionally, optimizing production workflows to minimize waste and recycle materials wherever possible contributes to a more sustainable manufacturing process.

Waste Reduction: Precision in embossing techniques, whether through etching or mold making, ensures minimal material waste. Accurate molds and etching tools reduce excess production and ensure that each piece of packaging meets the desired specifications without the need for rework or disposal of defective items.

| Sustainability Aspect | Embossing Method | Benefits |

|---|---|---|

| Materials | Recyclable or biodegradable | Reduces environmental impact |

| Inks | Water-based inks | Minimizes harmful chemical use |

| Energy Efficiency | Energy-efficient machinery | Lowers energy consumption |

| Waste Reduction | Precise etching and molding | Decreases material waste |

| Durability | Long-lasting embossing effects | Enhances product lifespan and appeal |

By integrating these sustainable practices into your embossing process, your cosmetic brand can offer packaging that not only looks premium but also aligns with environmental values. This approach not only appeals to eco-conscious consumers but also positions your brand as a responsible and forward-thinking entity in the cosmetic market.

Choosing the Right Embossing Method for Your Cosmetic Packaging Brand

Unsure which embossing technique aligns best with your brand’s goals? Let’s identify the key factors to help you choose the optimal method for your cosmetic packaging.

Selecting the appropriate embossing method5 depends on your brand’s specific needs, production volume, and desired design complexity to ensure optimal results.

Factors to Consider When Selecting Embossing

Choosing between logo etching and mold making involves evaluating several critical factors that can influence the effectiveness and efficiency of your packaging process.

Production Volume: Assessing the scale of your production is fundamental. If you anticipate large-scale manufacturing, mold making is more suitable due to its cost-effectiveness and consistency in high-volume runs. Conversely, for smaller batches or limited edition products, etching offers flexibility without the need for significant upfront investment.

Design Complexity: The intricacy of your logo and design elements plays a crucial role in this decision. Etching is superior for highly detailed and complex designs, allowing for precise engravings that capture every fine detail. Mold making, while excellent for maintaining uniformity, may not reproduce intricate designs as effectively unless the mold is of exceptionally high quality.

Cost Efficiency: Analyzing the cost implications is essential. Etching typically has lower setup costs for small runs, making it economically viable for limited production. Mold making involves higher initial costs due to mold fabrication but becomes more cost-efficient as production volume increases. Consider your budget and how it aligns with your production needs.

Flexibility and Adaptability: Consider how often you plan to update or change your designs. Etching offers greater flexibility, allowing you to modify designs with ease and minimal additional costs. Mold making requires creating new molds for each design change, which can be time-consuming and expensive.

Brand Longevity and Consistency: If your brand’s identity relies on consistent and long-term packaging, mold making provides the stability needed to maintain uniformity across all products. This consistency is vital for building and reinforcing brand recognition.

Lead Time and Production Speed: Evaluate your production timelines. Etching generally has a faster turnaround for small batches, enabling quicker responses to market demands or trends. Mold making may have longer lead times due to the mold creation process but excels in efficient production once the mold is in place.

| Consideration | Logo Etching | Mold Making |

|---|---|---|

| Production Volume | Small to medium runs | Large-scale production |

| Design Complexity | High detail and intricate designs | Consistent but less intricate |

| Cost Efficiency | Lower for small batches | More cost-effective for bulk |

| Flexibility | Easy to modify designs | Requires new molds for changes |

| Initial Investment | Lower setup cost | Higher due to mold creation |

| Lead Time | Shorter for small batches | Longer due to mold fabrication |

By carefully assessing these factors, you can make an informed decision that aligns with your brand’s objectives and operational capabilities. Whether you prioritize design flexibility, cost efficiency, or production consistency, selecting the right embossing method will enhance your cosmetic packaging and support your brand’s growth.

Conclusion

Selecting the right embossing method—whether etching for precision or mold making for consistency—enhances your packaging's appeal and strengthens your brand's presence in the market.

-

Understanding logo etching helps in appreciating its precision and suitability for detailed designs. ↩

-

Learning about mold making processes clarifies its efficiency for large-scale production. ↩

-

Exploring laser engraving provides insights into its advantages for intricate packaging designs. ↩ ↩

-

Knowing the benefits of injection molding machines highlights their role in consistent production. ↩ ↩ ↩ ↩

-

Understanding embossing enhances the appreciation of its impact on packaging aesthetics. ↩ ↩

-

Understanding foil stamping and spot UV highlights additional techniques to enhance packaging appeal. ↩ ↩

-

Recognizing the significance of B2B models explains the business dynamics in cosmetic packaging. ↩

-

Learning about sustainable materials supports eco-friendly packaging decisions. ↩ ↩ ↩ ↩

-

Knowing the applications of recycled paperboard promotes sustainable packaging choices. ↩ ↩

-

Exploring water-based inks reveals their environmental advantages in packaging. ↩ ↩

2.png)

](https://jinlinpackaging.com/wp-content/uploads/2024/11/What-is-Logo-Etching-and-How-Does-it-Differ-from-Mold-Making-in-Cosmetic-Packaging.jpg)

](https://jinlinpackaging.com/wp-content/uploads/2024/11/How-Does-Mold-Making-Work-for-Embossing-Cosmetic-Packaging.jpg)

](https://jinlinpackaging.com/wp-content/uploads/2024/11/Is-Etching-a-Better-Option-for-Fine-Details-or-Small-Cosmetic-Packaging-Runs.jpg)

](https://jinlinpackaging.com/wp-content/uploads/2024/11/Why-Custom-Logo-Embossing-Enhances-Cosmetic-Packaging-Appeal.jpg)

](https://jinlinpackaging.com/wp-content/uploads/2024/11/Eco-Friendly-and-Sustainable-Cosmetic-Packaging-with-Embossed-Logos.jpg)

](https://jinlinpackaging.com/wp-content/uploads/2024/11/Choosing-the-Right-Embossing-Method-for-Your-Cosmetic-Packaging-Brand.jpg)