Facing challenges integrating PCR plastic into cosmetic packaging? Discover effective steps to overcome these hurdles and ensure a smooth, sustainable transition for your packaging line.

PCR plastic offers a sustainable alternative for cosmetic packaging. Proper integration enhances product quality, minimizes environmental impact, and ensures long-term success for your packaging line.

Continue reading to learn the essential steps and best practices for effectively integrating PCR plastic into your cosmetic packaging line, ensuring a successful and sustainable transition.

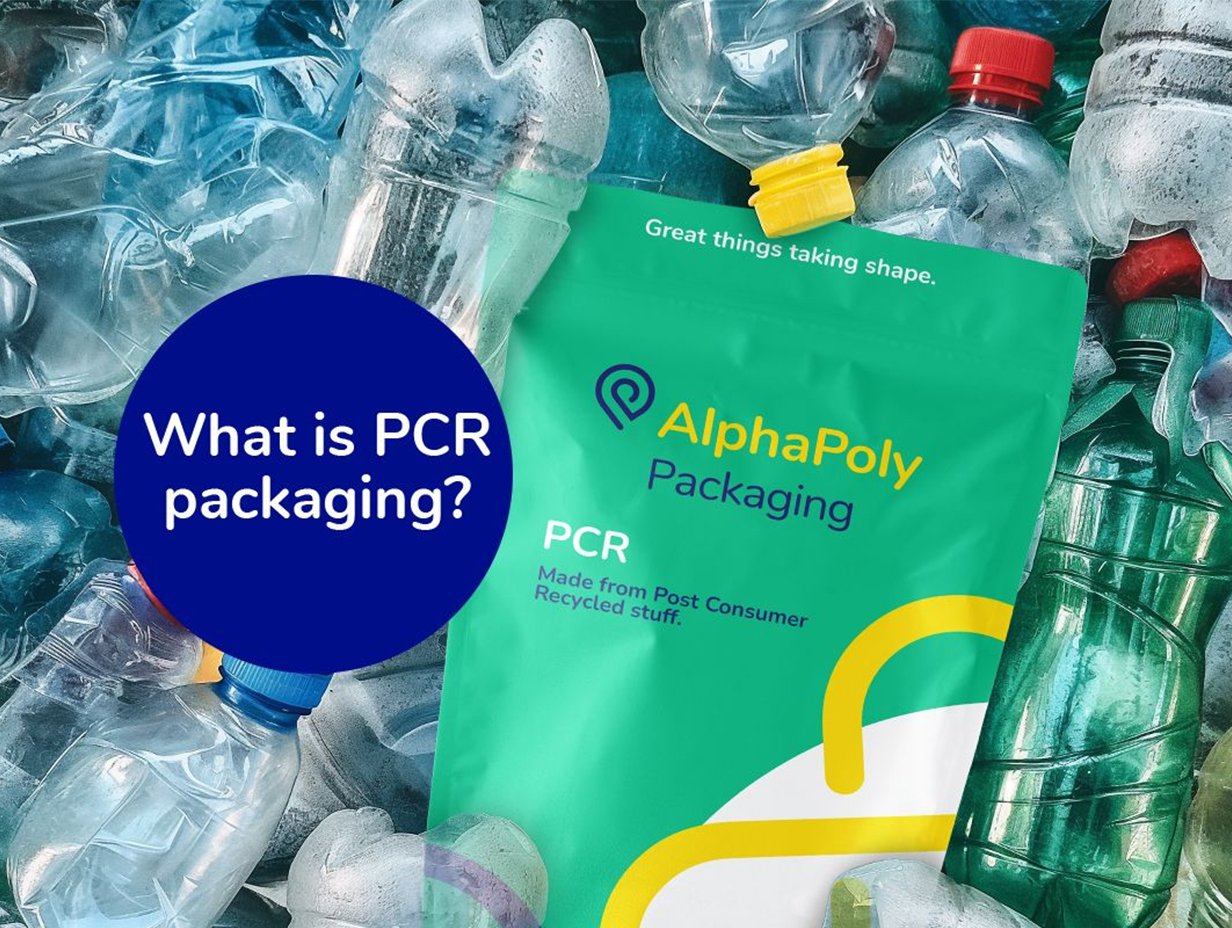

What is PCR plastic and Why is it Important for Cosmetic Packaging?

Struggling to find sustainable packaging1? PCR plastic2 recycles post-consumer materials3, offering an eco-friendly4 solution for cosmetic packaging.

PCR plastic, derived from post-consumer recycled materials, is increasingly used in cosmetic packaging to reduce environmental impact5 and meet consumer demand for eco-friendly products6.

PCR plastic is sourced from post-consumer recycled materials, making it a sustainable choice1 for cosmetic packaging. Adopting PCR plastic can significantly reduce waste and align your packaging line with sustainability goals1.

PCR plastic minimizes environmental impact and enhances eco-friendly4 packaging options. It is increasingly becoming a preferred material for sustainable cosmetic packaging solutions1.

PCR plastic is often seen as a green alternative1. Many cosmetic packaging manufacturers are adopting it as part of their sustainability practices1. But, how exactly does it help? First, it lowers carbon footprints5 by reducing the need for virgin plastic2. Second, it helps meet the increasing consumer demand for eco-friendly packaging6. As global attention turns to sustainability1, cosmetic brands look for ways to appeal to environmentally-conscious consumers6. However, despite these advantages, using PCR plastic comes with its own set of challenges, such as sourcing and quality control5.

Advantages of Using PCR plastic for Cosmetic Packaging

| Benefit | Explanation |

|---|---|

| Sustainability | Reduces reliance on virgin plastic and minimizes waste. |

| Brand Appeal | Attracts eco-conscious consumers who value sustainability. |

| Regulatory Compliance | Meets increasing regulatory standards7 for environmentally friendly products1. |

| Cost-Effective | Reduces costs associated with new plastic production. |

How to Start Integrating PCR plastic into Your Cosmetic Packaging Line?

Facing the transition to sustainable packaging? Integrating PCR plastic offers a viable path forward for your cosmetic line.

Integrating PCR plastic into your cosmetic packaging involves sourcing reliable materials7, adjusting designs, and ensuring compatibility with your production processes for a seamless transition.

The process starts with sourcing reliable PCR plastic suppliers7 and understanding the material’s compatibility with your packaging designs. This foundational step ensures that the recycled materials meet your quality and sustainability standards1.

Begin by identifying trusted suppliers who provide high-quality PCR materials2. Assessing your current packaging designs for compatibility with PCR plastic is crucial to accommodate its specific characteristics, such as melting points7 and structural properties7.

Transitioning to PCR plastic in your packaging line requires careful planning. Start by identifying trusted suppliers who offer high-quality PCR materials. Not all PCR plastic is created equal, so sourcing from a reputable cosmetic packaging supplier7 is key. Next, assess your current packaging designs. Some designs may need to be modified to accommodate the specific characteristics of PCR plastic, such as different melting points7 or structural properties7. Additionally, the integration process7 might require you to upgrade your machinery. Ensure your manufacturing equipment can handle the processing of PCR plastic to avoid delays or subpar results.

How to Find Reliable PCR plastic Suppliers?

| Key Criteria | Why It Matters |

|---|---|

| Certifications | Verifies that the PCR plastic meets regulatory standards7. |

| Product Range | Ensures they can supply the specific type of PCR plastic required. |

| Customer Support | Helps solve issues during the integration process. |

| Cost Efficiency | Balances sustainability with cost-effectiveness7. |

What Challenges Can You Expect When Using PCR plastic in Cosmetic Packaging?

Considering PCR plastic? Be aware of the potential challenges that come with its use in cosmetic packaging.

Using PCR plastic presents challenges such as material inconsistency5 and quality control issues, which can impact the final cosmetic packaging’s appearance and performance.

From sourcing to quality control, there are multiple challenges when using PCR plastic in cosmetic packaging. Understanding them helps mitigate potential risks.

One of the biggest challenges with PCR plastic is inconsistency in the material quality5. Since PCR plastic is made from recycled materials3, there can be variations in color, texture, and strength. This can lead to inconsistencies in the final product, which is a major concern for cosmetic packaging companies. Additionally, while PCR plastic is widely available, it may not always meet the specific quality or aesthetic standards that luxury brands expect. For high-end cosmetic packaging, maintaining a sleek, smooth finish is essential. Another challenge is cost—although PCR plastic is generally cheaper than virgin plastic, sourcing high-quality PCR materials can sometimes cost more, especially if you require specialized formulations.

Managing Quality Control

| Challenge | Solution |

|---|---|

| Inconsistent Material | Work closely with suppliers to ensure consistent quality. |

| Aesthetic Quality | Test and adjust formulations to match desired finish and texture. |

| Cost Fluctuations | Source from multiple suppliers to ensure competitive pricing. |

How to Ensure Your PCR Packaging Meets Regulatory Standards and Certifications?

Worried about compliance? Ensuring PCR packaging meets regulatory standards is essential for legal and consumer trust.

Ensuring your PCR packaging complies with global regulatory standards involves understanding regional laws, obtaining necessary certifications8, and partnering with certified suppliers to maintain compliance and build consumer trust.

Ensure that your PCR plastic packaging meets global regulatory standards to avoid potential legal issues and enhance brand trust.

Start by reviewing the packaging laws in your key markets—whether in the EU, the USA, or the Middle East. For instance, certain regions require certifications for the recycled content in your packaging. Certifications like the Global Recycled Standard (GRS)9 or Recycled Content Certification10 are crucial to ensure that your packaging meets legal standards. Furthermore, many cosmetic packaging companies are partnering with third-party certification bodies8 to prove the authenticity of their PCR packaging. By taking these steps, you not only comply with regulations but also build consumer trust in your sustainability practices.

Key Certifications for PCR Packaging

| Certification | Scope |

|---|---|

| Global Recycled Standard (GRS) | Verifies recycled content and social/environmental practices. |

| Recycled Content Certification | Verifies the percentage of recycled content in packaging. |

| ISO 14021 | Ensures claims of recycled material meet international standards. |

What Are the Long-Term Benefits of Using PCR plastic in Cosmetic Packaging?

Thinking long-term? Discover how PCR plastic can benefit your cosmetic business over time.

Using PCR plastic offers long-term advantages such as enhanced brand reputation6, cost savings6, and compliance with evolving environmental regulations, supporting sustained business growth and consumer loyalty6.

Beyond sustainability, PCR plastic enhances your brand’s reputation, reduces costs, and supports your overall environmental goals.

The long-term benefits of integrating PCR plastic into cosmetic packaging go beyond just environmental impact5. For businesses, it enhances brand value6 by showing a commitment to sustainability, which is increasingly important to consumers. In fact, studies show that consumers are willing to pay a premium for eco-friendly products6. Over time, using PCR plastic can help your company reduce reliance on virgin plastic, which is often subject to price fluctuations. In addition, it fosters stronger relationships with environmentally-conscious consumers6 who value brands with a clear sustainability agenda. On the regulatory side, by adopting PCR plastic early on, you’ll be ahead of the curve in meeting evolving global packaging standards7.

Long-Term Strategic Benefits

| Benefit | Explanation |

|---|---|

| Brand Loyalty | Consumers are more likely to stay loyal to eco-conscious brands6. |

| Cost Efficiency | Long-term savings from reduced virgin plastic costs2. |

| Regulatory Advantage | Stay ahead of future regulations with proactive adoption. |

Conclusion

Integrating PCR plastic in your cosmetic packaging line supports sustainability, reduces costs, and enhances brand value.

-

Explains the concept of sustainable packaging and its importance in reducing environmental impact. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Provides a definition of PCR plastic to help readers understand its role in sustainable packaging. ↩ ↩ ↩ ↩

-

Clarifies what post-consumer recycled materials are and their significance in recycling processes. ↩ ↩

-

Defines eco-friendly packaging and its benefits for both businesses and the environment. ↩ ↩

-

Details how PCR plastic affects the environment positively by reducing waste and carbon footprints. ↩ ↩ ↩ ↩ ↩ ↩

-

Explores the reasons behind the rising consumer preference for eco-friendly products and its impact on businesses. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Outlines the regulatory standards that PCR packaging must meet to ensure compliance and consumer trust. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Provides information on ISO 14021 and how it ensures recycled material claims meet international standards. ↩ ↩

-

Describes the GRS certification and its role in verifying recycled content and sustainable practices. ↩

-

Explains Recycled Content Certification and its importance in ensuring the recycled material percentage. ↩

2.png)