Are you looking for a packaging material that combines durability with sustainability for your cosmetics? Finding the right balance between protecting your products and meeting eco-friendly goals can be challenging. PP plastic provides an ideal solution, offering strength and flexibility while supporting environmentally responsible practices.

PP plastic has become a preferred choice in the cosmetic packaging industry because of its remarkable durability, lightweight design, and environmentally friendly characteristics. It not only preserves the quality of beauty products but also helps businesses meet sustainability targets.

Curious how PP plastic can elevate your cosmetic packaging? Keep reading to explore its benefits and why it's becoming the go-to material for the industry.

What is PP Plastic?

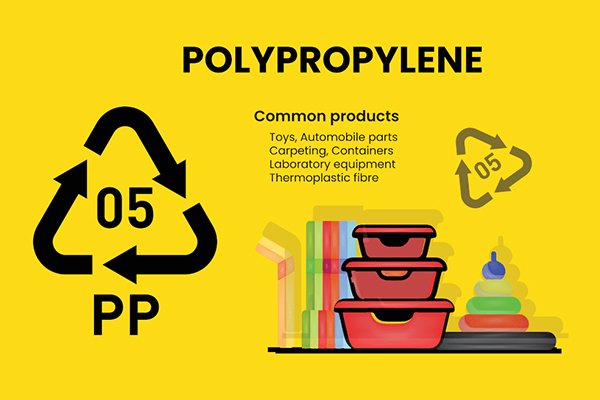

Polypropylene (PP) plastic1 is a versatile thermoplastic polymer2 used in a variety of applications, including cosmetic packaging3. Known for its resilience, PP is both lightweight and durable, making it perfect for packaging needs.

PP plastic is a lightweight, durable material used in packaging. Its resistance to wear and tear makes it ideal for cosmetic containers.

Why is PP Plastic So Popular for Packaging?

Struggling with unreliable packaging? PP plastic offers superior durability and flexibility, ensuring your cosmetic products are well-protected and visually appealing.

PP plastic has become a top choice for packaging materials due to its unique properties. It is resistant to chemical corrosion4, meaning it does not degrade easily when exposed to lotions, oils, and other cosmetic ingredients. Furthermore, PP is resistant to heat5, which helps preserve the contents in various climates.

Properties of PP Plastic

- Lightweight: Ideal for reducing shipping costs.

- Durable: Can withstand rough handling without breaking.

- Non-toxic6: Safe for contact with cosmetic products.

- Chemical resistance: Does not interact with cosmetic ingredients.

These features make it a go-to for manufacturers and brands seeking functional, safe, and reliable packaging for cosmetics.

Key Properties of PP Plastic

Facing challenges in selecting the right packaging material? PP plastic stands out with its exceptional chemical resistance4, high melting point7, and barrier properties8 capabilities.

PP plastic has several features that make it stand out from other materials in the cosmetic packaging industry. These include excellent chemical resistance, high melting point, and versatility in design.

What Makes PP Plastic Stand Out for Cosmetic Packaging?

Struggling to balance protection and design? PP plastic provides the ideal combination of heat resistance5 and barrier properties8, ensuring your cosmetics remain intact and high-quality.

Polypropylene has a high melting point, making it heat resistant, which is crucial for products stored in varying temperatures. It also offers excellent barrier properties that protect the contents from external elements like moisture and air. This helps to maintain the integrity and quality of the cosmetics inside.

In addition to its practical features, PP plastic can also be easily molded into various shapes and sizes, offering flexibility for custom cosmetic packaging designs. This versatility allows cosmetic brands to choose packaging that aligns with their aesthetic while maintaining functionality.

Advantages of PP Plastic for Cosmetic Packaging

| Feature | Advantage |

|---|---|

| High Melting Point7 | Withstands high temperatures during storage and transport. |

| Chemical Resistance4 | Protects cosmetics from chemical reactions or degradation. |

| Moldability | Easily molded into various shapes and designs for custom packaging. |

| Durability | Long-lasting, offering protection during shipping and handling. |

Common Applications of PP Plastic

Need reliable and customizable packaging? PP plastic is extensively used in various cosmetic containers, providing both durability and aesthetic flexibility.

PP plastic is used in a wide range of cosmetic packaging types, including bottles, jars, tubes, and cases. Its strength and ease of customization make it a favorite among cosmetic packaging manufacturers.

Where Can You Find PP Plastic in Cosmetic Packaging?

Looking for versatile packaging solutions? PP plastic is commonly used in various cosmetic packaging forms, from lip gloss tubes to mascara containers, ensuring both protection and style.

From lip gloss tubes to mascara containers, PP plastic is commonly used in various cosmetic packaging forms. Its durability and flexibility make it ideal for products that need to maintain their shape and protect the contents.

In addition to standard cosmetic packaging, PP plastic is often used for premium packaging lines due to its versatility. Brands that want to convey a high-quality product often use PP plastic as a base material, enhancing both the product's function and its aesthetic appeal.

Popular Products Using PP Plastic

- Lipstick Tubes: Durable and sleek packaging for lip products.

- Face Cream Jars: Protects sensitive creams from contaminants.

- Cosmetic Bottles: Prevents leakage and maintains the product's freshness.

These examples show how PP plastic supports a wide range of cosmetic packaging needs.

Is PP Plastic Safe for Packaging?

Concerned about safety? PP plastic is non-toxic and FDA-approved6 material, ensuring your cosmetic products remain safe and uncontaminated.

Yes, PP plastic is considered safe for cosmetic packaging. It is non-toxic and does not leach harmful chemicals into the product.

Why Is PP Plastic Safe for Cosmetic Packaging?

Struggling with product contamination? PP plastic’s FDA approval and non-porous surface ensure your cosmetics stay pure and free from harmful substances.

PP plastic is food-safe and FDA-approved, which ensures that it is safe for packaging cosmetics that come into contact with the skin. Its inert nature means that it will not react with the products inside, making it a trusted material for brands that prioritize safety.

In addition to its chemical resistance, PP plastic’s non-porous surface helps prevent bacteria and other microorganisms from growing, making it ideal for products like lotions, gels, and creams that are often stored in containers for extended periods.

Safety Features of PP Plastic

- FDA Approved: Meets safety standards for direct contact with cosmetic products.

- Non-toxic: Free from harmful chemicals like BPA.

- Non-porous Surface: Prevents bacterial contamination.

Advantages of Using PP Plastic in Cosmetic Packaging

Looking for cost-effective and sustainable options? PP plastic offers numerous benefits, including affordability, recyclability9, and a premium feel for your cosmetic products.

The benefits of PP plastic in cosmetic packaging go beyond durability. It is also cost-effective, recyclable, and offers a premium feel for a variety of cosmetic products.

How Does PP Plastic Compare to Other Materials?

Unsure about material choices? PP plastic surpasses other plastics like PET10 and PVC10 with its superior heat resistance, flexibility, and sustainability, making it a better option for cosmetic packaging.

PP plastic has several advantages over other plastics, such as PET (Polyethylene Terephthalate) and PVC (Polyvinyl Chloride). Compared to PET, PP has a higher resistance to heat, which makes it more durable under varying environmental conditions. Moreover, PP plastic is more flexible, which allows for greater customization in packaging design.

When compared to PVC, PP plastic is less prone to cracking or breaking, making it a safer option for cosmetic packaging. Additionally, PP is a more sustainable choice, as it can be recycled and repurposed, unlike PVC, which is less eco-friendly.

Advantages of PP Over Other Materials

| Feature | PP Plastic | PET Plastic | PVC Plastic |

|---|---|---|---|

| Heat Resistance | High | Medium | Low |

| Flexibility | High | Medium | Low |

| Durability | High | Medium | Low |

| Sustainability | Recyclable9 | Recyclable | Difficult to Recycle |

Conclusion

PP plastic is the ideal choice for cosmetic packaging, offering durability, safety, and sustainability at a competitive price.

-

Learn more about Polypropylene (PP) plastic to understand its applications and benefits. ↩

-

Understand what thermoplastic polymers are and their properties. ↩

-

Discover the role of cosmetic packaging in product protection and presentation. ↩

-

Find out how chemical corrosion impacts plastic materials like PP and their durability. ↩ ↩ ↩

-

Learn about heat resistance in plastics and why it's important for packaging applications. ↩ ↩

-

Understand the safety standards that make PP plastic suitable for cosmetic packaging. ↩ ↩

-

Discover why a high melting point is crucial for the durability and functionality of packaging materials. ↩ ↩

-

Learn about barrier properties and how they protect cosmetic products from external factors. ↩ ↩

-

Find out about the recyclability of PP plastic and its benefits for sustainable packaging. ↩ ↩

-

Compare PET and PVC plastics with PP plastic to understand their advantages and disadvantages. ↩ ↩