Plastic injection molding is essential in creating consistent, cost-effective, and custom cosmetic packaging. It overcomes challenges like design precision and high-volume production.

Plastic injection molding is a key technique for producing high-quality cosmetic packaging. It ensures precise designs, consistent quality, and scalability, making it ideal for custom, cost-effective, and sustainable packaging solutions in the beauty industry.

In this article, we'll explore how plastic injection molding can revolutionize cosmetic packaging with its versatility and advantages for brands.

What is Plastic injection molding1?

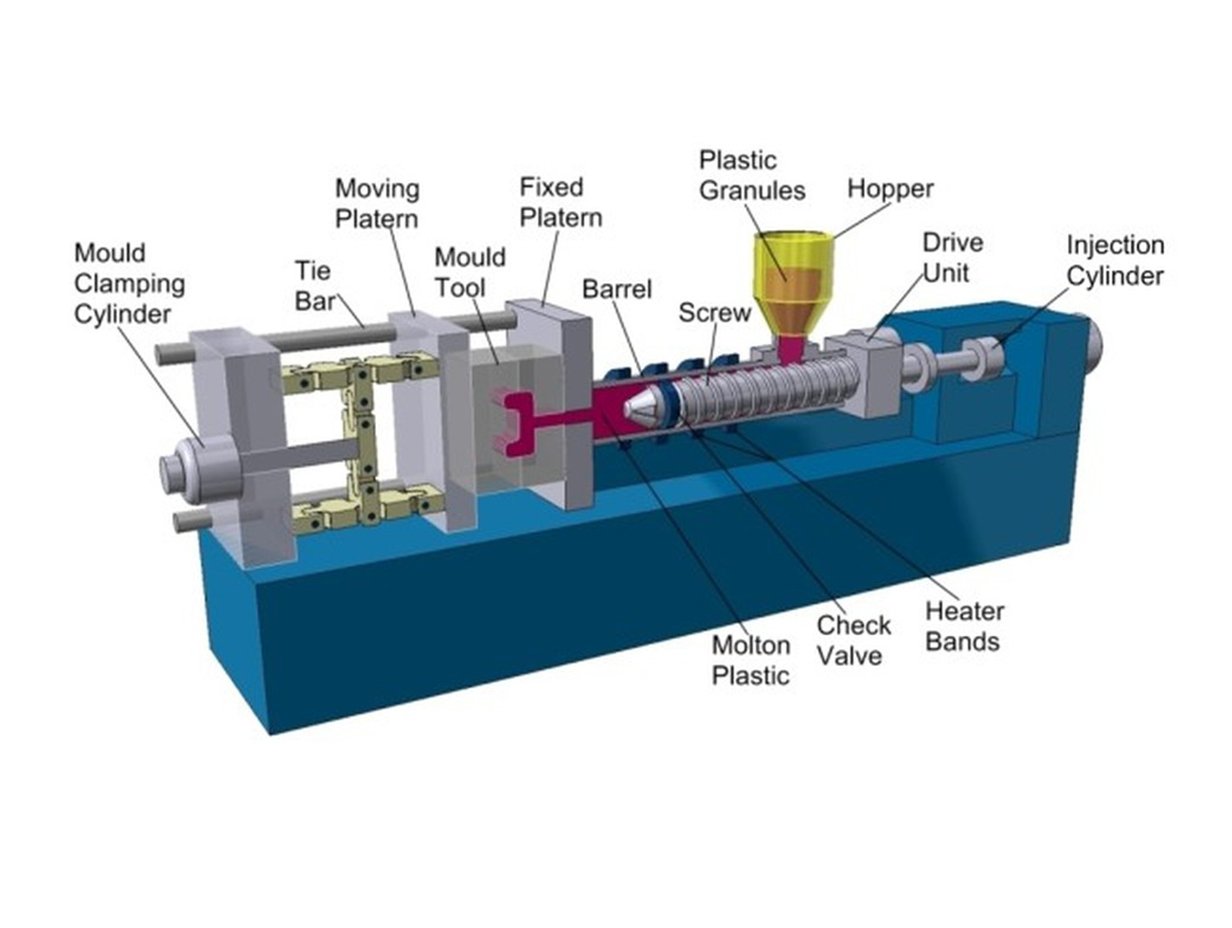

Plastic injection molding1 is a process where melted plastic is injected into a mold to create detailed products. This technique is widely used for various industries, including cosmetics packaging2.

Plastic injection molding1 uses molten plastic to form precise shapes, offering efficiency and flexibility in cosmetic packaging2 design.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/injmachin.gif)

The Injection molding process3

Injection molding process3 begins with plastic pellets4, which are melted and injected into a mold. Once cooled, they take the shape of the mold. This method is known for mass production5, which makes it ideal for cosmetic packaging manufacturers2.

Cost Efficiency and Scalability

This process ensures cost efficiency by enabling mass production5. It's particularly beneficial for businesses looking to scale their cosmetic packaging2 production quickly without compromising quality.

Material Versatility

Different materials can be used in injection molding3, offering a range of options for cosmetic product packaging2, including sustainable plastics6 and luxurious finishes.

How Does Plastic injection molding1 Work?

The core of injection molding3 involves heating plastic material4 to a liquid state and injecting it into a pre-designed mold. This allows for precise shapes and features that are crucial for cosmetic packaging2.

Injection molding3 works by melting plastic and injecting it into molds to create detailed cosmetic packaging2 with precise designs.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/How-Does-Plastic-Injection-Molding-Work.jpg)

Mold Design and Customization

The design of the mold plays a crucial role in the outcome. For cosmetics2, custom molds allow companies to produce unique packaging that reflects the brand's identity.

Speed and Efficiency in Production

The speed of injection molding3 enables cosmetic packaging companies2 to produce large quantities quickly, ensuring timely delivery to meet market demand.

Advanced Technologies in Injection molding3

Technological advancements, such as automation7 and computer-aided design (CAD)7, have made injection molding3 even more precise and efficient, pushing the limits of creativity in cosmetic packaging2.

The Key Benefits of Plastic injection molding1 for Cosmetic Packaging2

Injection molding3 offers several advantages, especially for the cosmetic packaging2 industry. These benefits include cost-effectiveness, customizability, and consistency in production.

Plastic injection molding1 offers cost savings, customization, and consistency, making it an ideal choice for producing cosmetic packaging2.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/The-Key-Benefits-of-Plastic-Injection-Molding-for-Cosmetic-Packaging.jpg)

Customization Options

Injection molding3 allows for intricate and unique cosmetic packaging2 designs. This process enables the creation of custom logos, intricate textures, and precise features that elevate the product’s appearance.

High-Quality and Durable Packaging

Injection molding3 produces durable and high-quality packaging. The process ensures consistent wall thickness and tight seals, which are important for the safety and presentation of cosmetic products.

Sustainable plastics6 for Packaging

Plastic injection molding1 also opens the door for more sustainable packaging6 solutions. Companies can choose recyclable materials8 or biodegradable materials9, aligning with the growing demand for eco-friendly cosmetic packaging2.

Common Applications of Plastic injection molding1 in Cosmetic Packaging2

Plastic injection molding1 is widely used in producing cosmetic packaging2 products like lip gloss tubes, mascara tubes, and cream jars. This process ensures precision and quality across all these applications.

From lip gloss tubes to cream jars, plastic injection molding1 is used extensively in the cosmetic packaging2 industry due to its precision and adaptability.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/Common-Applications-of-Plastic-Injection-Molding-in-Cosmetic-Packaging.jpg)

Packaging Components Produced by Injection molding3

Cosmetic packaging companies2 use injection molding3 to produce a variety of products such as containers, pumps, closures, and caps. These components must be precise and durable to meet the cosmetic industry's standards.

Injection molding3 in Luxury Cosmetic Packaging2

Luxury cosmetic brands rely on injection molding3 for packaging that demands sophistication. The technique offers a variety of finishes, including gloss, matte, and even custom textures.

Cosmetic Packaging2 for Sustainability

Sustainable packaging6 is a growing trend. Injection molding3 can be adapted to use recyclable8 and biodegradable materials9, meeting the needs of environmentally conscious consumers.

Important Design Factors for Plastic injection molding1 in Cosmetic Packaging2

When designing for plastic injection molding1 in cosmetic packaging2, several factors need consideration, such as material choice10, mold design, and production costs.

Key design factors like material selection[^10, mold design, and cost efficiency are critical when using plastic injection molding1 for cosmetic packaging2.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/Important-Design-Factors-for-Plastic-Injection-Molding-in-Cosmetic-Packaging.jpg)

Material Selection10 and Its Impact on Packaging Design

Choosing the right material10 is essential in determining the final appearance and functionality of the packaging. Materials like PET[^10, HDPE10, and PP10 are commonly used in cosmetic packaging2 and affect the product's recyclability and durability.

The Importance of Mold Design for Detail

For custom cosmetic packaging2, mold design must reflect the brand’s aesthetics. Intricate designs, such as embossing or unique shapes, require precise molds to achieve the desired effect.

Cost and Production Timeline Considerations

The initial cost of mold creation can be high, but the long-term production efficiency of plastic injection molding1 makes it a cost-effective choice for mass production5.

How Plastic injection molding1 Supports Sustainable Cosmetic Packaging2

Sustainability is becoming increasingly important in the cosmetic industry2, and plastic injection molding1 can help reduce the environmental footprint of packaging.

Plastic injection molding1 supports sustainability by enabling the use of recyclable8 and biodegradable materials9 for cosmetic packaging2.

](https://jinlinpackaging.com/wp-content/uploads/2024/12/How-Plastic-Injection-Molding-Supports-Sustainable-Cosmetic-Packaging.jpg)

Biodegradable Materials9 in Injection molding3

With the rise in demand for eco-friendly packaging, biodegradable materials9 are being used in injection molding3. These materials decompose naturally, reducing waste in landfills.

Recycling8 and Reusing Materials

Plastic injection molding1 can use recycled plastic pellets4, which helps reduce waste and resource consumption. By choosing recyclable materials8, cosmetic packaging companies2 can reduce their environmental impact.

Reduced Carbon Footprint with Efficient Production

injection molding3 is energy-efficient, allowing for large volumes of cosmetic packaging2 to be produced quickly with minimal waste, helping companies reduce their overall carbon footprint.

Conclusion

Plastic injection molding is essential for producing high-quality, cost-effective, and sustainable cosmetic packaging solutions.

-

Plastic injection molding - Learn more about the fundamentals of plastic injection molding and its applications. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Cosmetic packaging - Discover the latest trends and innovations in cosmetic packaging design. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Injection molding process - Understand the step-by-step process of injection molding and its industrial significance. ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩ ↩

-

Plastic pellets - Find out what plastic pellets are and how they are used in manufacturing processes. ↩ ↩ ↩

-

Mass production - Explore the benefits and challenges of mass production in various industries. ↩ ↩ ↩

-

Sustainable plastics - Learn about sustainable plastics and their impact on the environment. ↩ ↩ ↩ ↩

-

Computer-aided design (CAD) - Discover how CAD technology enhances precision and efficiency in design and manufacturing. ↩ ↩

-

Recyclable materials - Understand the importance of recyclable materials in reducing environmental waste. ↩ ↩ ↩ ↩ ↩

-

Biodegradable materials - Explore biodegradable materials and their role in sustainable product development. ↩ ↩ ↩ ↩ ↩

-

PET - Learn about PET and its applications in packaging and manufacturing. ↩ ↩ ↩ ↩ ↩