Worried about product quality due to air or contamination? Airless pump bottles ensure freshness and longevity efficiently.

Airless pump bottles prevent air exposure, maintaining product freshness and extending shelf life. They dispense precisely, ensuring hygiene and minimizing waste. Ideal for cosmetics, they offer eco-friendly, high-quality packaging solutions, enhancing user experience and preserving product integrity.

Read on to discover the unique advantages of airless pump bottles and how they can elevate your brand, improve product quality, and meet growing sustainability demands.

What Is an Airless Pump Bottle?

Finding packaging that maintains product freshness and prevents contamination can be a challenge. Airless pump bottles provide the solution, offering advanced protection from air exposure, ensuring your cosmetic products stay fresh and pure for longer.

Airless pump bottles are designed to protect cosmetics from air exposure, which can lead to contamination and spoilage. This innovative packaging solution helps extend product longevity and preserves the purity of sensitive formulations, offering an ideal choice for preserving cosmetic quality.

Understanding Airless Pump Bottle Technology

- Airless pump bottles use a vacuum or positive pressure system to dispense products without air entry.

- This technology minimizes oxidation and contamination, preserving product quality.

- A piston design maintains a consistent vacuum, ensuring precise product dispensing.

- Airless pumps prevent bacterial growth, ideal for sensitive formulations.

Advantages of Airless Pump Bottles

| Feature | Airless Pump Bottles | Traditional Bottles |

|---|---|---|

| Air Protection | Yes | No |

| Product Preservation | High | Low |

| Dispensing Control | Precise | Variable |

| Aesthetic Appeal | Modern Design | Basic Design |

| Sustainability | Reusable Components | Limited Recycling |

Choosing airless pump bottles not only preserves the integrity of your products but also enhances the overall user experience. Their sleek design adds a touch of luxury, making your cosmetics stand out on the shelves.

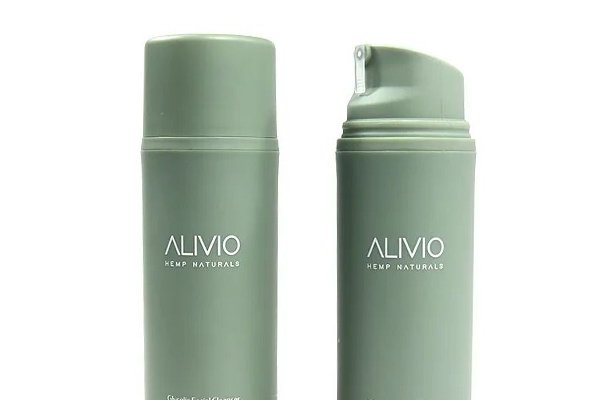

How Does an Airless Pump Bottle Work?

Confused about how airless pump bottles work? Airless pump bottles operate by creating a vacuum or positive pressure inside, dispensing product without air contact, ensuring freshness and preventing contamination for longer-lasting cosmetic products.

Airless pump bottles function by using a vacuum or positive pressure to dispense products, eliminating air contact and preserving product integrity. This technology helps keep cosmetics fresh, prevents contamination, and extends the shelf life of sensitive formulations.

Mechanism of Airless Pump Bottles

- Airless pump bottles prevent air entry with a unique dispensing system.

- Pressing the pump moves a piston to dispense the product, maintaining a vacuum.

- No air seepage ensures protection from oxidation and contamination.

- My experience shows this mechanism's reliability and efficiency in preventing wastage.

- The design includes a nozzle to avoid direct contact, enhancing hygiene and safety.

Components of Airless Pump Systems

| Component | Function |

|---|---|

| Pump Head | Dispenses the product |

| Piston | Maintains vacuum or pressure |

| Nozzle | Prevents air and contamination entry |

| Container | Holds the cosmetic product |

| Seal | Ensures airtight closure |

Understanding these components helps in appreciating the sophistication of airless pump bottles. Each part plays a crucial role in ensuring that the product remains fresh and uncontaminated, providing a superior packaging solution for high-quality cosmetics.

What Are the Benefits of Airless Pump Bottles?

Worried about product degradation and hygiene concerns? Airless pump bottles offer multiple benefits: enhancing product stability, minimizing contamination risks, and providing precise dispensing, all of which improve both product quality and user satisfaction.

Airless pump bottles are designed to enhance the stability of cosmetic products by reducing exposure to air and contaminants. With precise dispensing, they improve hygiene and minimize contamination risks, ensuring longer-lasting quality and a better experience for the consumer.

Enhanced Product Stability and Longevity

One of the primary benefits of airless pump bottles is their ability to maintain product stability over time. By preventing air from entering the container, these bottles minimize oxidation and contamination, which can degrade active ingredients in skincare and makeup products. In my experience, using airless pump bottles has extended the shelf life of products, ensuring that they remain effective and safe for consumers longer. This not only enhances customer satisfaction but also reduces product waste, contributing to more sustainable packaging practices.

Benefits for Users and Brands

| Benefit | Description |

|---|---|

| Product Preservation | Maintains product integrity and effectiveness |

| Hygiene | Reduces exposure to air and contaminants |

| Precise Dispensing | Controls the amount of product dispensed |

| User Experience | Easy and mess-free application |

| Brand Image | Enhances the perception of quality and innovation |

These advantages make airless pump bottles a valuable investment for cosmetic brands. They not only protect the product but also enhance the overall user experience, leading to increased customer loyalty and brand reputation.

What Products Are Best Suited for Airless Pump Bottles?

Unsure which products benefit most from airless packaging? Airless pump bottles are perfect for skincare products, serums, creams, and cosmetics that need protection from air exposure and precise dispensing to maintain quality and effectiveness.

Airless pump bottles are ideal for skincare products, serums, creams, and other air-sensitive cosmetics. These bottles preserve product integrity by minimizing air exposure, ensuring long-lasting quality and providing precise dispensing to meet the needs of delicate formulations.

Ideal Products for Airless Pump Packaging

- Airless pump bottles are ideal for products prone to oxidation and contamination.

- Skincare items like serums and moisturizers benefit from preserved active ingredient efficacy.

- Makeup products maintain texture and color consistency with airless packaging.

- Precise dispensing ensures right amount delivery, reducing waste and enhancing application.

Product Categories Benefiting from Airless Pumps

| Product Type | Benefit |

|---|---|

| Serums | Preserves active ingredients |

| Moisturizers | Maintains texture and consistency |

| Anti-Aging Creams | Extends product shelf life |

| Liquid Foundations | Prevents color and texture changes |

| Eye Creams | Ensures hygienic application |

Selecting the right products for airless pump bottles can significantly enhance their performance and user satisfaction. By choosing this packaging, brands can ensure that their products remain effective and appealing throughout their lifecycle.

Why Are Airless Bottles a Growing Trend?

Curious why more brands are adopting airless packaging? Airless bottles are becoming increasingly popular because they preserve product quality, enhance the user experience, and align with sustainable packaging trends, making them a smart choice for modern brands.

Airless bottles are gaining traction as a preferred packaging solution due to their ability to preserve the quality of cosmetic products, improve the user experience, and meet the growing demand for sustainable packaging. They combine practicality with eco-friendly benefits.

Market Trends Driving Airless Packaging

- The cosmetic industry is shifting towards sustainable and user-friendly packaging.

- Airless pump bottles combine functionality with eco-friendliness, meeting consumer demands.

- Consumers value product preservation and hygiene, pushing brands to adopt better packaging.

- Premium skincare products drive demand for sophisticated options like airless pumps.

- My experience shows investing in airless bottles boosts customer trust and loyalty, indicating a commitment to quality.

Factors Contributing to the Popularity of Airless Pumps

| Factor | Description |

|---|---|

| Product Preservation | Maintains efficacy of active ingredients |

| Hygiene and Safety | Reduces contamination risks |

| Sustainability | Often reusable and made from recyclable materials |

| User Convenience | Easy and precise dispensing |

| Brand Differentiation | Enhances brand image with innovative packaging |

These factors collectively contribute to the growing trend of airless pump bottles in the cosmetic industry. By addressing both consumer needs and environmental concerns, airless packaging stands out as a forward-thinking solution that aligns with modern market demands.

How to Choose Reliable Airless Bottle Suppliers?

Facing challenges in finding trustworthy suppliers? Choosing reliable airless bottle suppliers is crucial to ensure product quality, on-time delivery, and a strong partnership that will meet your cosmetic packaging needs and expectations.

Selecting the right airless bottle supplier is essential for ensuring quality and reliability. A trustworthy supplier can provide high-quality packaging, meet delivery deadlines, and foster a long-term partnership that supports your brand’s goals and helps maintain product integrity.

Key Considerations When Selecting Suppliers

Choosing the right supplier is crucial for maintaining the quality and reliability of your cosmetic packaging. Here are some factors to consider:

-

Quality Standards: Ensure the supplier adheres to international quality certifications and standards. High-quality materials and manufacturing processes are essential for airless pump bottles to function effectively.

-

Customization Capabilities: Look for suppliers that offer customization options, such as logo printing and unique design features. This allows your brand to stand out and maintain a consistent image across your product line.

-

Production Capacity: Assess the supplier's ability to meet your demand, especially if you plan to scale your business. A supplier with ample production capacity and efficient logistics can prevent delays and ensure timely delivery.

-

Sustainability Practices: With the growing emphasis on eco-friendly packaging, it's important to choose suppliers that prioritize sustainable practices, such as using recyclable materials and minimizing waste.

-

Customer Support: Reliable customer service is vital for addressing any issues that may arise. A supplier that offers excellent support can help resolve problems quickly and maintain a smooth business relationship.

Evaluating Supplier Reliability

| Criterion | Importance |

|---|---|

| Quality Certifications | Ensures adherence to high manufacturing standards |

| Customization Options | Allows for brand-specific packaging designs |

| Production Capacity | Meets current and future order demands |

| Sustainability | Aligns with eco-friendly brand values |

| Customer Service | Provides timely and effective support |

By carefully evaluating these criteria, you can select a supplier that not only meets your current needs but also supports your long-term business growth. Building a strong partnership with a reliable supplier is essential for the success and reputation of your cosmetic brand.

Conclusion

Airless pump bottles elevate cosmetic packaging with superior protection, user experience, and sustainability.