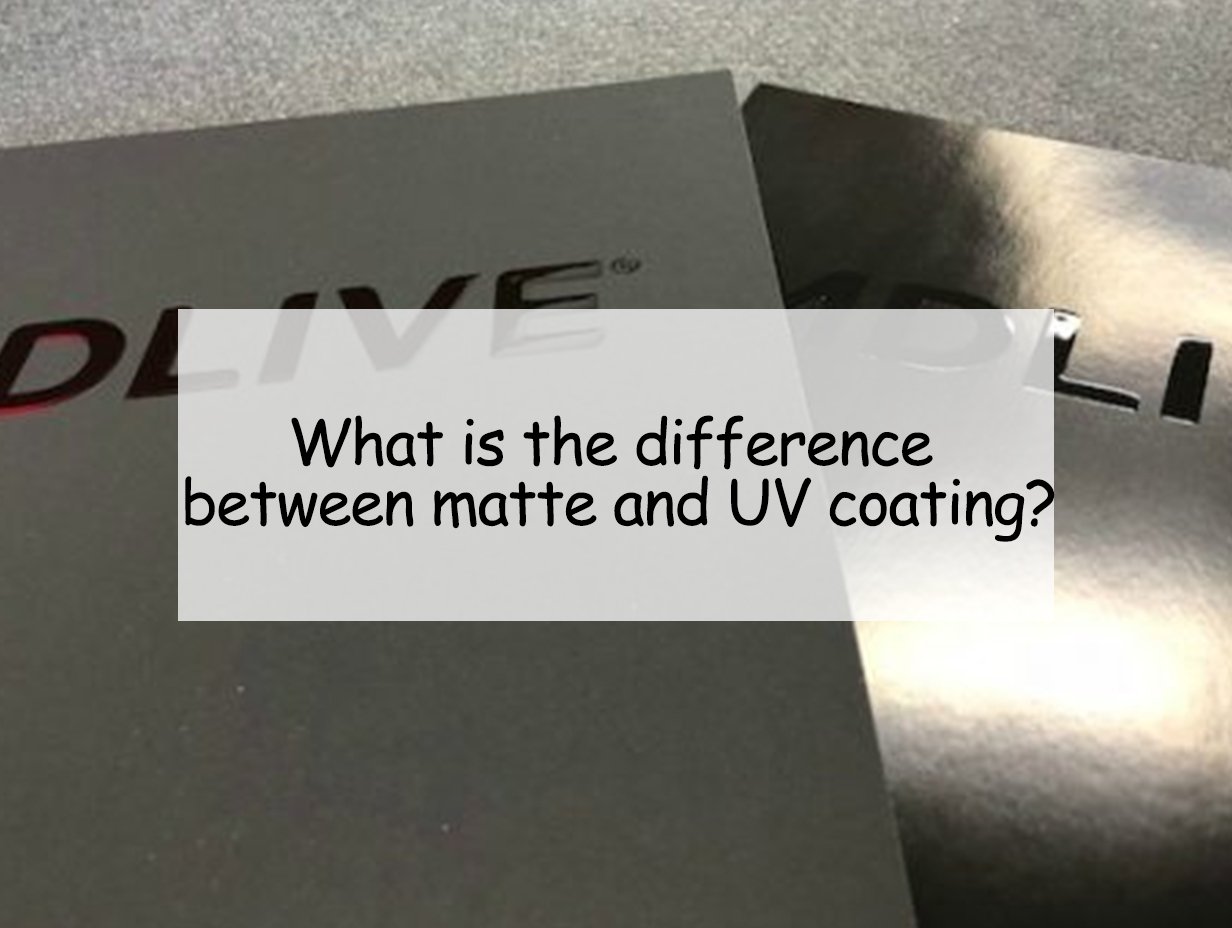

If you’ve ever wondered about the difference between matte and UV coating, you’re not alone. Both are popular finishes, but they offer very different looks and qualities.

Matte coating gives a soft, non-reflective finish, while UV coating offers a glossy, shiny effect that can make colors pop. Both have unique benefits depending on the look and durability you’re after.

Understanding the differences between these two coatings can help you choose the best option for your products. Let’s dive into the specifics of each.

What is UV Coating?

If you're aiming for a high-gloss, durable finish on your packaging, UV coating could be the solution you’re seeking. But does it wear off over time?

UV coating is a high-gloss varnish applied to printed materials and cured using ultraviolet light. This process creates a durable finish that enhances colors and offers protection against wear and tear.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/What-is-UV-Coating.jpg)

UV coating is applied to printed materials and then cured using ultraviolet light. This process hardens the coating, creating a glossy, durable layer. It’s often used on items like business cards, brochures, and packaging to create a high-end, shiny look. UV coating is not just about appearance—it also provides protection against scratches, fading, and moisture.

Benefits of UV Coating

- Glossy finish: UV coating provides a high-gloss finish that enhances colors and graphics.

- Durability: The coating is resistant to damage, including water and fading.

- Protection: UV coating acts as a protective layer against wear and tear.

| Feature | UV Coating |

|---|---|

| Gloss level | High Gloss |

| Durability | Highly Durable (scratch and water-resistant) |

| Protection | Protection from fading, smudging, and moisture |

What is Matte Coating?

If you're looking for a more subdued, elegant look for your packaging, matte coating might be the perfect choice. But how does it stack up against UV coating?

Matte coating creates a smooth, non-reflective finish that offers a subtle, understated aesthetic. It also provides a tactile experience, giving the packaging a unique feel that many find appealing.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/What-is-Matte-Coating.jpg)

Matte coating, unlike UV coating, creates a dull finish that doesn’t reflect light. This gives the printed material a more natural, understated look. It’s often chosen for items where a high-gloss finish would be distracting, such as high-end brochures, business cards, or packaging that needs a more classic or elegant feel.

Benefits of Matte Coating

- Elegant finish: Offers a sophisticated, non-reflective look.

- Tactile feel: Many people find matte surfaces more enjoyable to touch.

- Professional appeal: Often used for luxury products to evoke a sense of class and quality.

| Feature | Matte Coating |

|---|---|

| Gloss level | Non-reflective (dull finish) |

| Durability | Moderate durability (more prone to fingerprints) |

| Protection | Less protection from moisture and dirt compared to UV |

UV Coating vs. Matte Coating Durability

When it comes to durability, matte and UV coatings offer different advantages. Which one holds up better over time?

UV coating is far more durable than matte coating. It offers superior resistance to scratches, fading, and moisture, making it the better option for high-traffic areas or products exposed to regular wear and tear.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/UV-Coating-vs-Matte-Coating-Durability.jpg)

UV coating’s durability is one of its biggest selling points. The curing process creates a hardened layer that protects the printed material from scratches, smudges, and moisture. On the other hand, matte coating, while still durable, is more susceptible to wear and tear. It’s prone to showing fingerprints and can fade more easily under certain conditions. However, matte coating is often chosen for its softer, more sophisticated finish, even if it means sacrificing a little durability.

Durability Comparison

| Feature | UV Coating | Matte Coating |

|---|---|---|

| Scratch resistance | High (due to hardened finish) | Moderate (more prone to scratches) |

| Fading | Resistant to fading | May fade over time |

| Moisture resistance | Highly resistant | Less resistant to moisture |

Cost Difference Between UV Coating and Matte Coating

Is there a big price difference between matte and UV coatings? Let’s break down the costs involved in each option.

UV coating generally costs more than matte coating due to the specialized equipment and curing process required. Matte coatings are often less expensive but still offer a premium look.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/Cost-Difference-Between-UV-Coating-and-Matte-Coating.jpg)

UV coating tends to be more expensive than matte coating for a few reasons. First, the process involves specialized UV curing equipment and often requires more intricate handling. Second, UV-coated products are generally more durable, which can justify the higher cost. Matte coating, while less expensive, can still provide a premium finish but doesn’t offer the same level of protection or gloss. If you’re working within a budget but want an elegant look, matte coating may be a more cost-effective choice.

Cost Comparison

| Feature | UV Coating | Matte Coating |

|---|---|---|

| Cost | Higher (due to specialized equipment) | Lower (more basic application) |

| Finish | Glossy and durable | Soft and elegant, but less durable |

| Use Case | Best for products requiring durability | Ideal for luxury products needing a sophisticated look |

Environmental Adaptability: UV Coating vs. Matte Coating

Print coatings’ hidden environmental costs often go unnoticed. While UV and matte finishes boost visual appeal, their ecological footprints diverge sharply—one threatens ecosystems, the other offers cautious hope. Which minimizes harm?

UV coatings are more durable and weather-resistant but often rely on energy-intensive curing and non-recyclable materials. Matte coatings, typically solvent-free and easier to recycle, may have a lower environmental impact if made with plant-based or biodegradable additives. Material composition and production methods ultimately determine their eco-friendliness.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/Environmental-Adaptability-UV-Coating-vs-Matte-Coating.jpg)

UV coatings are durable and resistant to moisture, UV rays, and physical wear. However, the UV curing process uses energy, and some UV coatings may contain chemicals that are harmful to the environment. Matte coatings, on the other hand, tend to be more eco-friendly, especially if made from water-based or biodegradable materials. This makes matte coating a better choice for companies looking to reduce their environmental footprint. However, its durability may not match the long-lasting protection of UV coatings.

Environmental Impact Comparison

| Feature | UV Coating | Matte Coating |

|---|---|---|

| Durability | Highly durable, better protection | Less durable, more prone to wear |

| Environmental Impact | Potentially harmful chemicals involved | More eco-friendly, if water-based |

| Energy Use | Requires energy for UV curing | Less energy-intensive |

Is UV Coating Better?

Are you looking to enhance your product’s finish and durability? Choosing the right coating can make or break the final look, longevity, and environmental impact. Let’s explore the options!

While UV coating provides a high-gloss, durable finish, the choice depends on your specific needs. For eco-friendly, subtle finishes, matte coatings offer a better alternative. Understanding these options is key to achieving the desired result.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/Is-UV-Coating-Better.jpg)

Whether UV coating is better depends largely on your needs. If you require a high-gloss, durable finish, UV coating is your best bet. It enhances colors and protects printed materials from wear and fading. However, if you’re after a softer, more understated look, matte coating may be a better choice. It offers elegance and a tactile finish but doesn’t provide the same durability as UV coating. Choosing the right coating ultimately depends on your product’s purpose and the environment it will be exposed to.

Pros and Cons of UV Coating vs Matte Coating

| Feature | UV Coating | Matte Coating |

|---|---|---|

| Glossiness | High gloss, enhances colors | Non-reflective, elegant |

| Durability | Highly durable, water and scratch-resistant | Moderate durability, prone to smudging |

| Environmental Impact | Potential for harmful chemicals | More eco-friendly, if water-based |

Does UV Coating Wear Off?

Curious if UV coating stands the test of time? Whether it’s for packaging or print, knowing its longevity can save you from unexpected wear and tear. Let’s dive into the details!

UV coating is highly durable, but exposure to extreme conditions can cause it to wear off over time. With proper care and maintenance, its finish can remain intact, ensuring long-lasting protection.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/Does-UV-Coating-Wear-Off.jpg)

While UV coating is highly durable, it can still show signs of wear if exposed to constant abrasion or harsh conditions. For example, packaging subjected to rough handling may eventually lose some of its glossy finish. However, UV coating is still more resistant to wear than matte finishes, making it a better option for products that require frequent handling. It’s important to note that UV-coated packaging can maintain its pristine look for a longer time if handled with care and stored properly.

| Durability Factor | UV Coating |

|---|---|

| Scratch Resistance | High, but can wear off with heavy abrasion |

| Exposure to Sunlight | UV coating can resist fading, but long exposure may cause some deterioration |

| Handling | Can wear off if the packaging is subjected to rough handling |

UV coating will not last forever, but it is definitely more durable than other finishes when used properly.

Is UV Coating Scratch Resistant?

Choosing the right finish for your packaging is crucial for both aesthetics and durability. Worried about scratches ruining the look? Let’s explore why UV coating is your go-to solution for scratch-resistant packaging.

UV coating provides strong scratch resistance. Its hardened resin layer protects packaging surfaces from minor abrasions, keeping your product looking new longer and ensuring lasting durability.

](https://jinlinpackaging.com/wp-content/uploads/2024/11/Is-UV-Coating-Scratch-Resistant.jpg)

UV coatings are designed to be tough and offer scratch resistance. The resin used in UV coating is cured under ultraviolet light, which creates a hard surface that resists scratches much better than other finishes. This makes UV coating an ideal choice for products that are likely to be handled frequently or stored in environments where scratching could be a concern. However, it’s important to keep in mind that while UV coating is scratch-resistant, it is not entirely scratch-proof. Severe impacts or abrasive materials can still cause damage to the coating.

| Feature | UV Coating |

|---|---|

| Scratch Resistance | High resistance to minor scratches |

| Ideal Use Case | Frequent handling and rough environments |

| Vulnerability | Not completely scratch-proof, but more durable than matte coatings |

If scratch resistance is a priority, UV coating is a great choice. It offers better protection than matte coatings, though it may still show damage with heavy abrasion.

Does UV Coating Wear Off a Cube?

Ever wondered if UV coating wears off differently on cubes compared to other shapes? Understanding how UV coating performs on various surfaces can help you choose the best option for your packaging.

The wear of UV coating on a cube depends on handling. While high-contact areas may show signs of wear, UV coating remains one of the most durable finishes, even on geometric shapes like cubes.

When UV coating is applied to a cube or any other shape, the general rules of wear and tear still apply. High-contact areas, such as edges or corners, may show signs of wear more quickly than flat surfaces. However, UV coating will still offer superior protection compared to matte coatings in these situations. The coating's hardness ensures that the surface resists fading and scratches, but it can still be affected by constant friction or impact. For packaging with intricate shapes or parts that experience frequent contact, UV coating remains one of the best choices for long-lasting durability.

| Shape | UV Coating Performance |

|---|---|

| Flat Surfaces | High durability, maintains finish |

| Edges and Corners | Wear may occur with heavy contact |

| Intricate Designs | UV coating still offers good protection |

UV coating will generally offer long-lasting protection, even on products with non-flat surfaces, but care should still be taken to avoid rough handling.

Conclusion

In summary, UV and matte coatings both have unique benefits. UV coating excels in durability and gloss, while matte coating offers a refined, eco-friendly alternative. Choose based on your product's needs.